Instrument DOI: 10.60551/a0g5-8n60

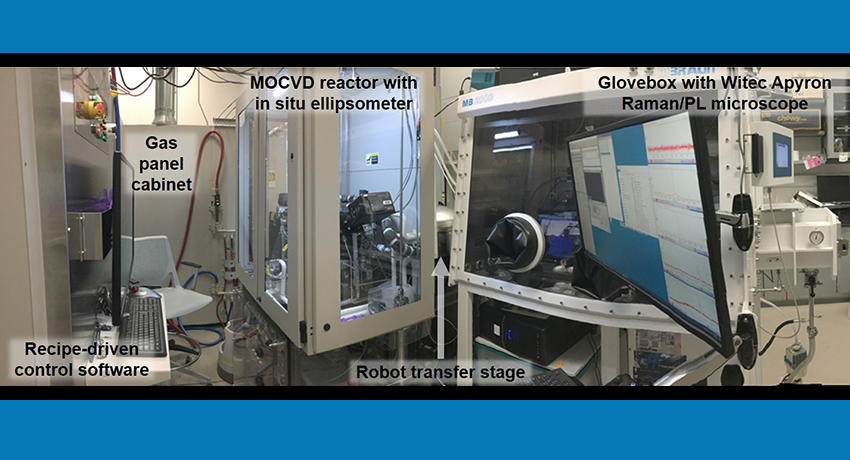

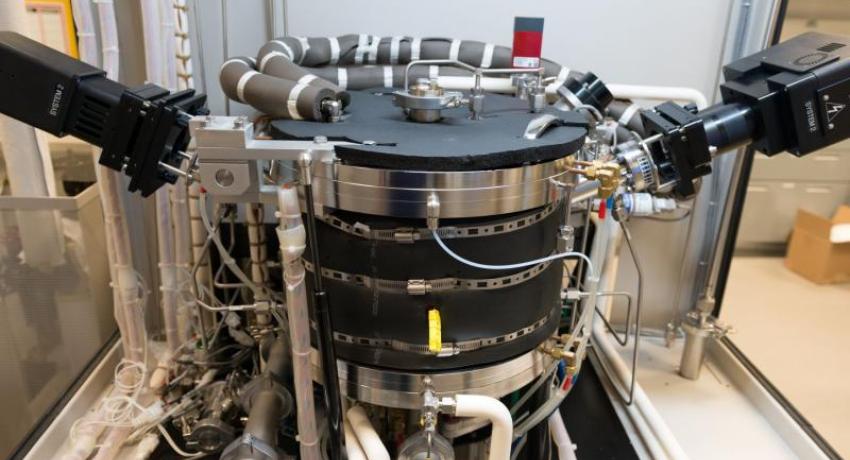

MOCVD2 is a custom designed multi-module system from CVD Equipment Corporation. The system includes a load lock and high vacuum robotic transfer stage with three additional ports. A stainless-steel chamber for metalorganic chemical vapor deposition (MOCVD) of chalcogenides is connected to one of the ports. The chamber consists of temperature-controlled wall and flanges, removable quartz liners and a rotating, resistively heated 2” diameter substrate holder for substrate temperatures up to 1000 °C. The MOCVD reactor includes two purged optical ports for in situ spectroscopic ellipsometry and a third for sample viewing.

The chamber exhaust includes cold-finger traps for chalcogen removal and a chemically resistant rotary vane pump that enables system operation from 10 to 700 Torr. The gas manifold is comprised of welded stainless-steel tubing with metal gasket seal fittings, pneumatically controlled valves, pressure controllers and mass flow controllers. Six bubbler manifolds are available for liquid or solid precursors two of which include double dilution and two which can be maintained at elevated temperature (up to 200oC) for low vapor pressure sources. Three pressure balanced vent/run manifolds are available for metal, chalcogen and dopant precursors.

System operation is controlled by CVD WinPrCTMsoftware which includes recipe-driven control and data logging. The system has an interlocked safety system including toxic gas monitoring, H2 detection and other alarms for safe operation. A pyrolyzer/water scrubber equipped with a sodium hydroxide neutralization system treats the reactor effluents to safe limits.

A robotic transfer stage enables transfer of samples directly from the MOCVD growth chamber into a custom designed Mbraun glovebox for optical characterization. Samples can also be loaded into the glovebox through a vacuum purged antechamber. A WITec Apyron confocal microscope is housed in the glovebox to enable ambient-controlled Raman and photoluminescence measurement. The Witec microscope is fully automated with joystick controller to enabling automated change of lasers (532 nm and 633nm), gratings (300, 600, and 1800 grooves/mm), objective lenses (x5, x10, x50, x100), focus (z height) and stage motion (x-y location), etc. The small footprint of the glovebox analysis chamber (50 in. x 35 in.) was enabled by vertical integration of the WITec microscope and optical fiber coupling with the laser sources and UHTS 600 spectrometer located on top of the glovebox.

Raman Instrument DOI: 10.60551/a534-xs21

See the full list of available thin film samples.

- Load lock and high vacuum robot transfer stage

- Stainless steel deposition chamber with temperature-controlled walls

- Resistive heater for 2” diameter substrates with rotation

- Removable quartz liner and gas inlets in deposition chamber

- 3 purged optical ports on deposition chamber for in situ characterization

- 3 pressure balanced vent/run manifolds

- 6 bubblers manifolds for liquid/solid sources (2 double dilution, 2 high temperature)

- 4 gas source lines (H2Se, H2S, etc.)

- Toxic gas monitoring by integrated gas detection/exhaust and scrubber/safety system

- CVD WinPrCTM software for recipe-driven control and data logging

- M-2000 in situ spectroscopic ellipsometer (J.A. Woollam) XI-210 with NIR upgrade

- MBraun glovebox with WITec Apyron confocal Raman/photoluminescence microscope

- Wafer scale process developed: WS2, WSe2 and MoS2 monolayers on 2” c-plane sapphire

- Metal Precursors: Mo(CO)6, W(CO)6

- Chalcogen Precursors: H2S, H2Se, Diethyl Telluride

- Carrier gas: Purified hydrogen or nitrogen

- List of currently available samples

“Step engineering for nucleation and domain orientation control in WSe2 epitaxy on c-plane sapphire,” H. Zhu, T. Choudhury, A. Bansal, B. Huet, K. Zhang, A. Puretzky, S. Bachu, K. York, T. Mc Knight, N. Trainor, K. Wang, R. Makin, S. Durbin, S. Huang, N. Alem, V. Crespi, A.C.T. van Duin and J.M. Redwing, Nature Nanotechnology (2023) in press. https://doi.org/10.21203/rs.3.rs-2180223/v1.