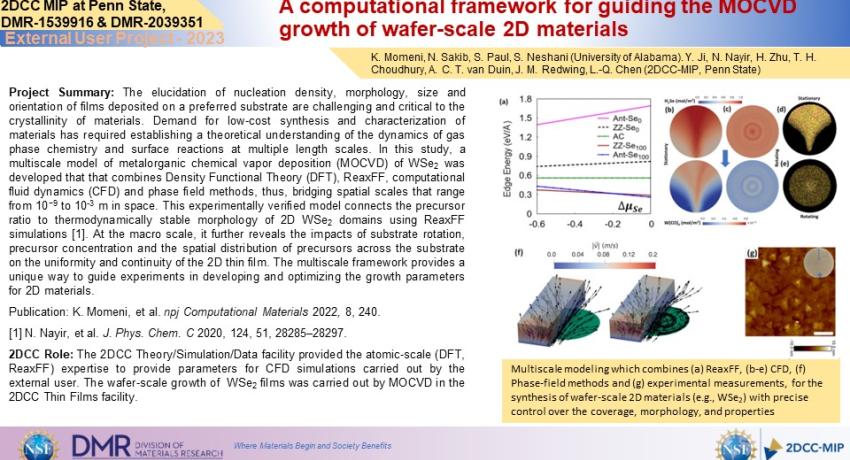

Project Summary: The elucidation of nucleation density, morphology, size and orientation of films deposited on a preferred substrate are challenging and critical to the crystallinity of materials. Demand for low-cost synthesis and characterization of materials has required establishing a theoretical understanding of the dynamics of gas phase chemistry and surface reactions at multiple length scales. In this study, a multiscale model of metalorganic chemical vapor deposition (MOCVD) of WSe2 was developed that that combines Density Functional Theory (DFT), ReaxFF, computational fluid dynamics (CFD) and phase field methods, thus, bridging spatial scales that range from 10−9 to 10-3 m in space. This experimentally verified model connects the precursor ratio to thermodynamically stable morphology of 2D WSe2 domains using ReaxFF simulations [1]. At the macro scale, it further reveals the impacts of substrate rotation, precursor concentration and the spatial distribution of precursors across the substrate on the uniformity and continuity of the 2D thin film. The multiscale framework provides a unique way to guide experiments in developing and optimizing the growth parameters for 2D materials.

Publication: K. Momeni, et al. npj Computational Materials 2022, 8, 240.

[1] N. Nayir, et al. J. Phys. Chem. C 2020, 124, 51, 28285–28297.

2DCC Role: The 2DCC Theory/Simulation/Data facility provided the atomic-scale (DFT, ReaxFF) expertise to provide parameters for CFD simulations carried out by the external user. The wafer-scale growth of WSe2 films was carried out by MOCVD in the 2DCC Thin Films facility.

What Has Been Achieved: A multiscale model for WSe2 MOCVD was developed using ReaxFF, CFD and Phase field methods. At the atomic scale, using reactive MD simulations based on DFT calculations, it provides the relationship between the ratio of precursor concentrations and stable morphology of 2D materials; At the macroscale, it connects experimentally controllable parameters with concentration of precursor and its gradient over the substrate; It combines the information from both nanoscale and macroscale simulations to predict the coverage and uniformity of as-grown 2D materials.

Importance of the Achievement: This computational framework provides a unique alternative to exhaustive trial-and-error experimentations and a powerful tool to develop and optimize the synthesis of new 2D materials. It can further serve as an observer for controllers of the growth process, providing the feedback loop capability, thus, precise control over the growth process, which opens new routes to design and fabricate the next generation of nanodevices for application in quantum computing and artificial intelligence.

Unique Feature(s) of the MIP that Enabled this Achievement: In-house expertise on DFT and ReaxFF simulations, and high-quality, wafer-scale 2D material synthesis

(If Applicable) Publication: K. Momeni, Y. Ji, N. Nayir, H. Zhu, T. H. Choudhury, A. C. T. van Duin, J. M. Redwing, L.-Q. Chen, “A computational framework for guiding the MOCVD growth of wafer-scale 2D materials,”, npj computational materials 8(1), 240 (2022).

Acknowledgments: This project is partly supported by the University of Alabama, the NSF-CAREER under the NSF cooperative agreement CBET-2042683, and 2D Crystal Consortium – Material Innovation Platform (2DCC-MIP) under NSF cooperative agreements DMR-1539916 and DMR-2039351 and the I/UCRC Center for Atomically Thin Multifunctional Coatings (ATOMIC) seed project SP001-17. The authors gratefully acknowledge use of the resources of the Alabama Water Institute and Alabama Transportation Institute at The University of Alabama. Y.Z.J. and L.Q.C. also acknowledge the generous support by the Hamer Foundation through a Hamer Professorship.