As Philadelphia’s first zero-waste certified business, we have earned gold status by diverting at least 90% of the material from our business from becoming landfill waste by creating recycled…

-

Research fuels your safety, health, and future. Learn how Penn State research protects what matters most.

Research fuels your safety, health, and future. Learn how Penn State research protects what matters most. -

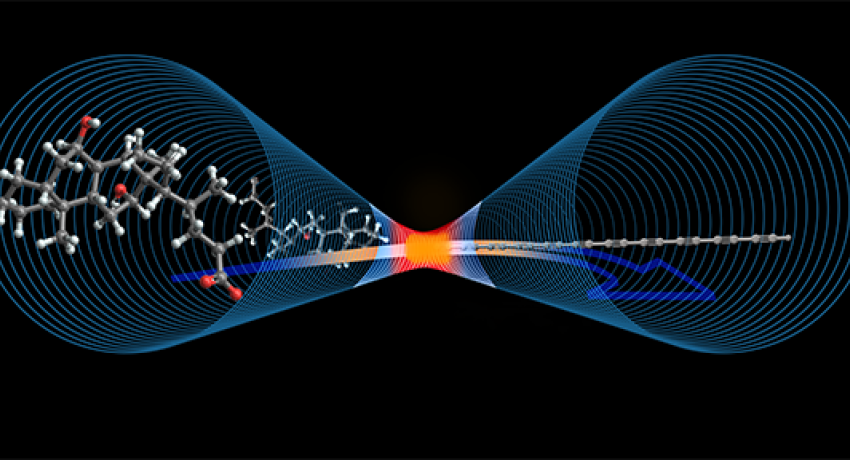

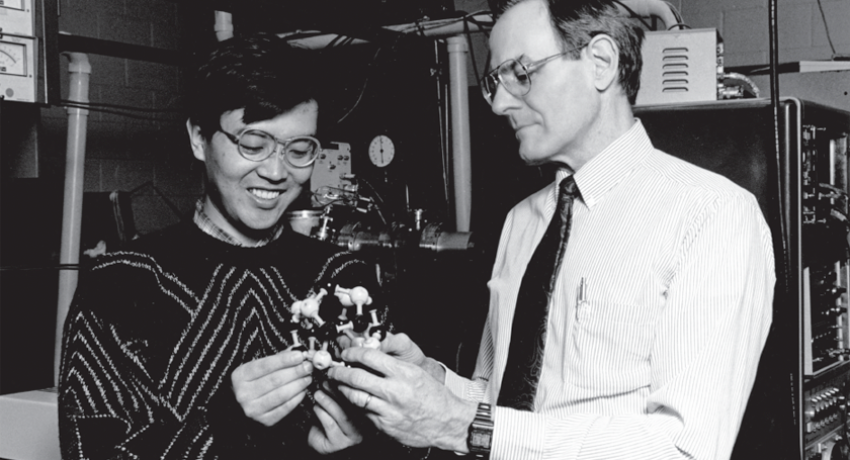

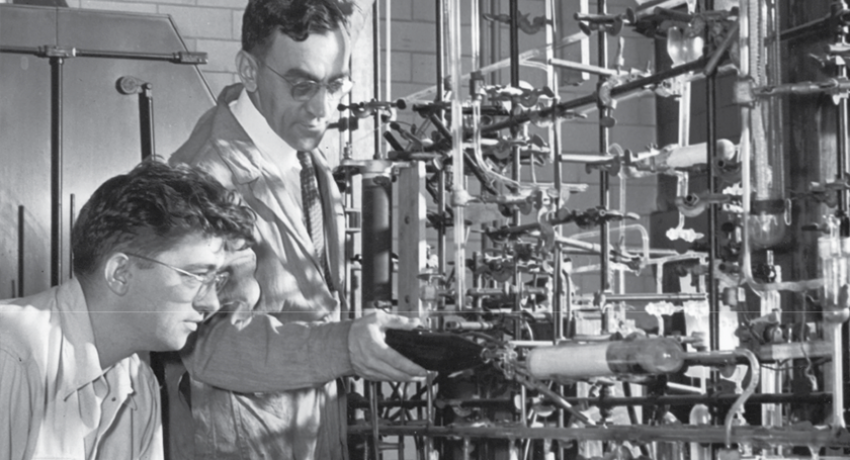

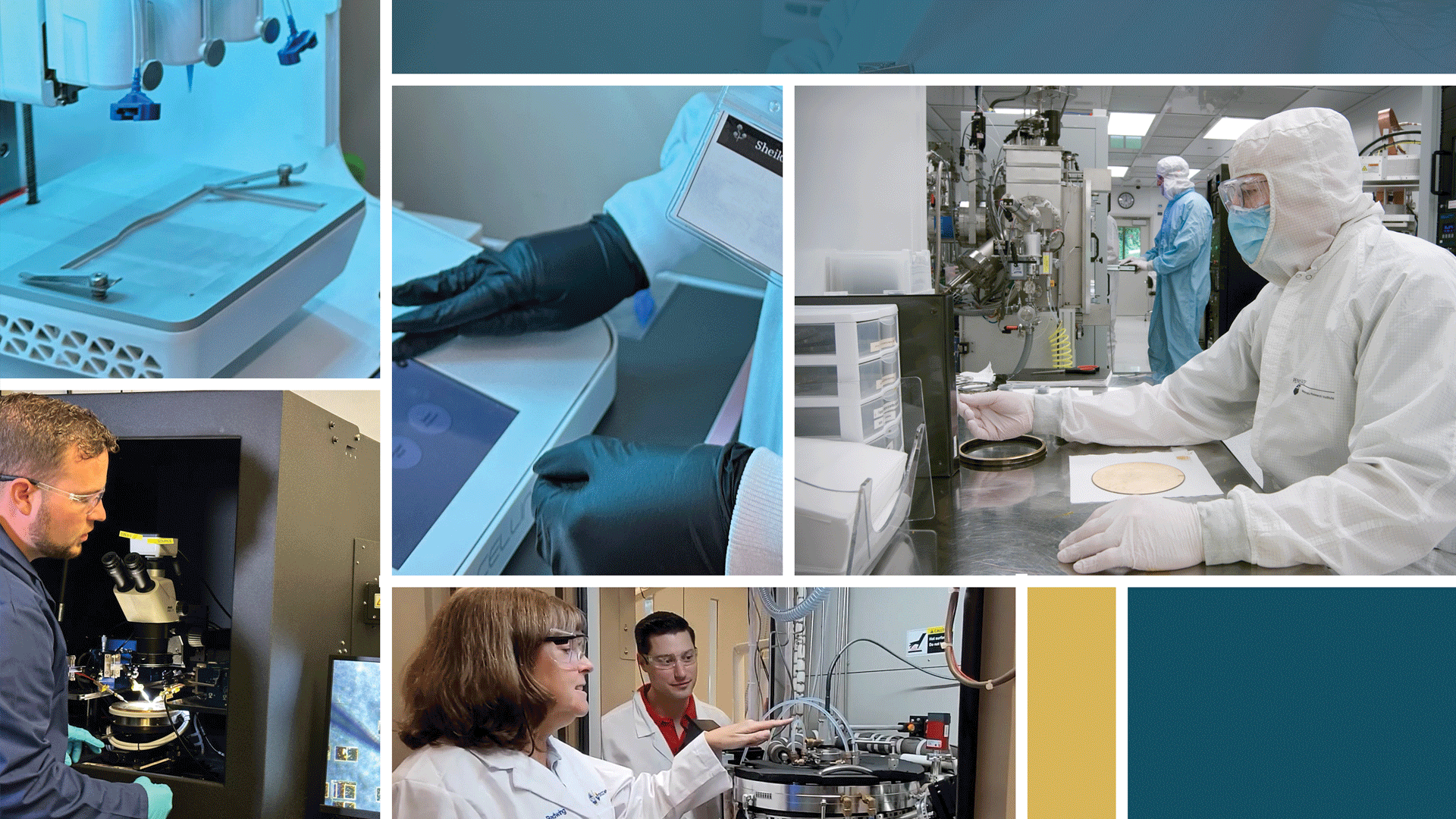

Interdisciplinary research brings together the physical and life sciences with engineering and computation to solve the most complex problems.

Interdisciplinary research brings together the physical and life sciences with engineering and computation to solve the most complex problems. -

Featured articles about Penn State's strengths in semiconductor research and discovery

Featured articles about Penn State's strengths in semiconductor research and discovery -

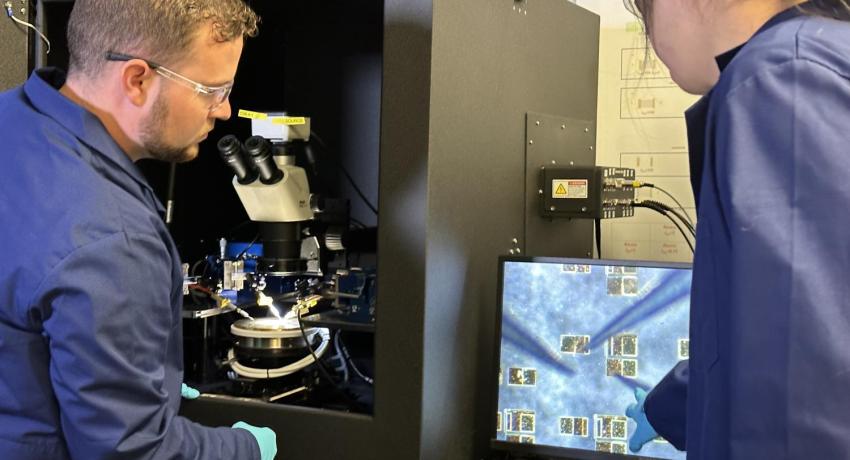

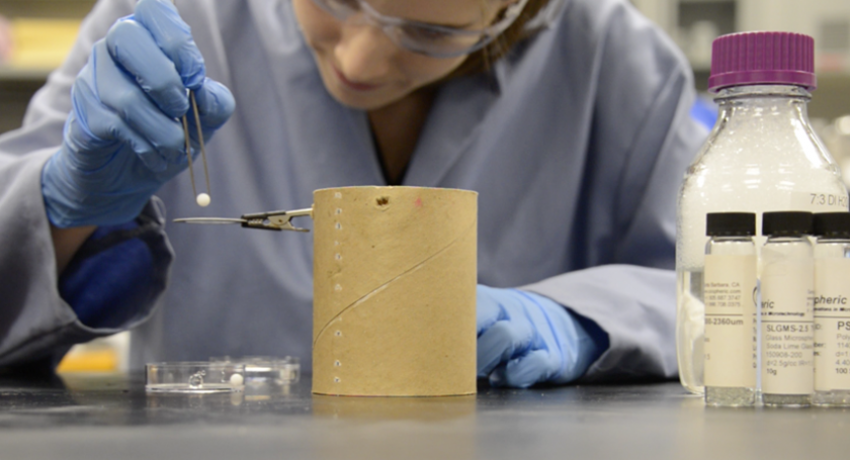

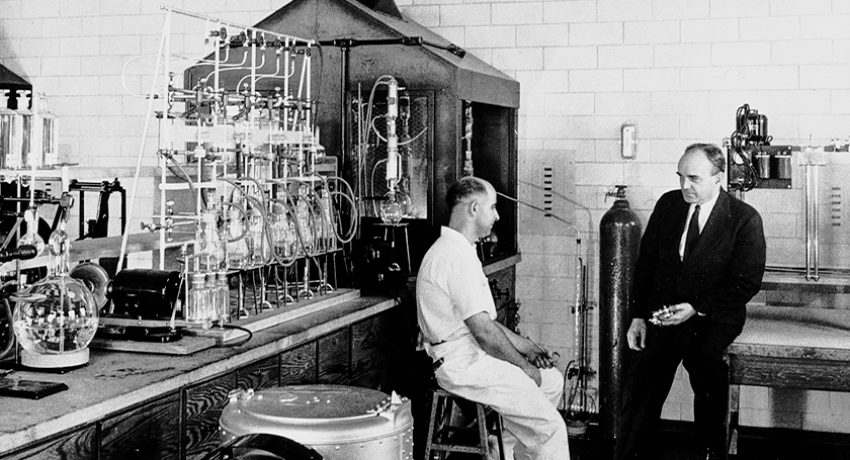

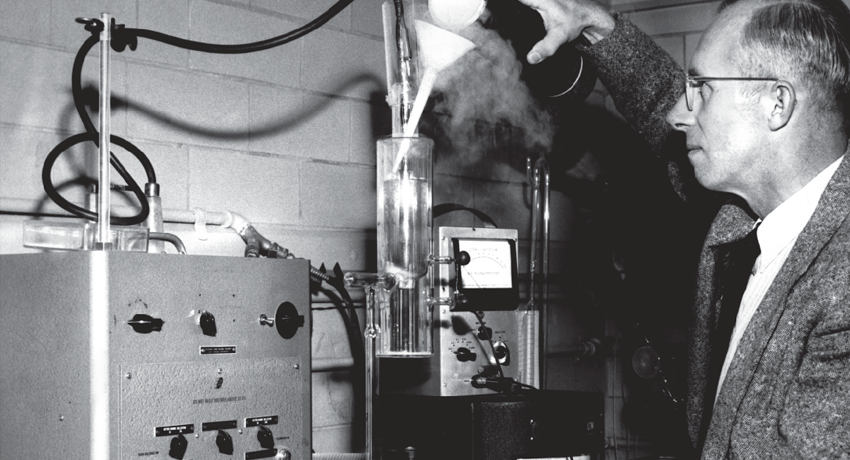

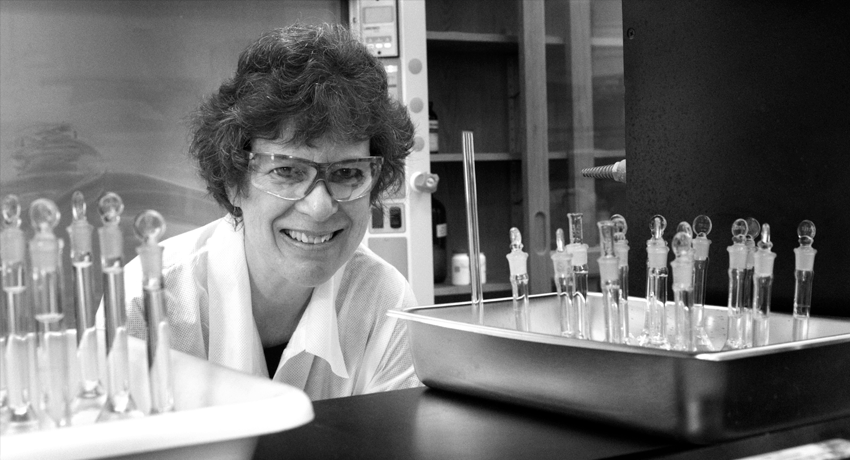

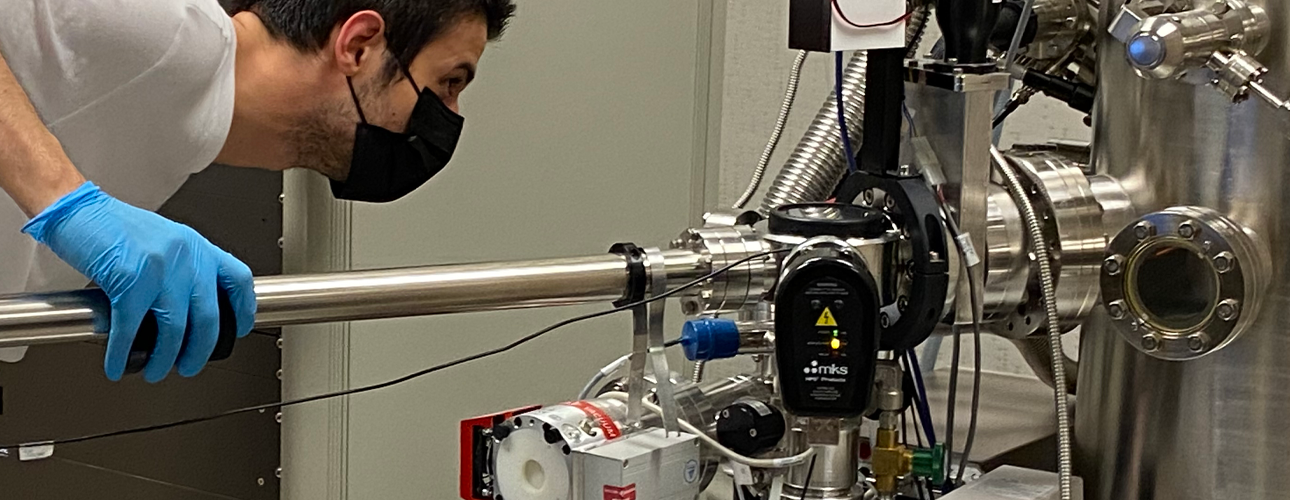

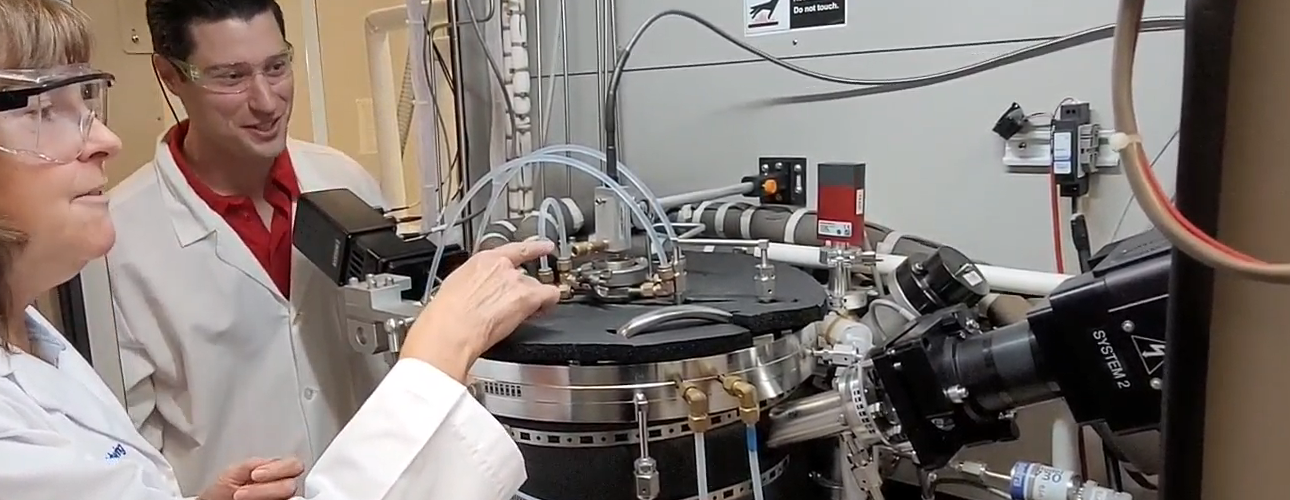

MCL is a fully-staffed, open access, analytical research facility charged with enabling research and educating the next generation of highly qualified researchers.

MCL is a fully-staffed, open access, analytical research facility charged with enabling research and educating the next generation of highly qualified researchers. -

The Nanofab saves companies the expense of maintaining their own state-of-the-art equipment and provides a highly skilled technical staff dedicated to working with companies in Pennsylvania and world wide.

The Nanofab saves companies the expense of maintaining their own state-of-the-art equipment and provides a highly skilled technical staff dedicated to working with companies in Pennsylvania and world wide. -

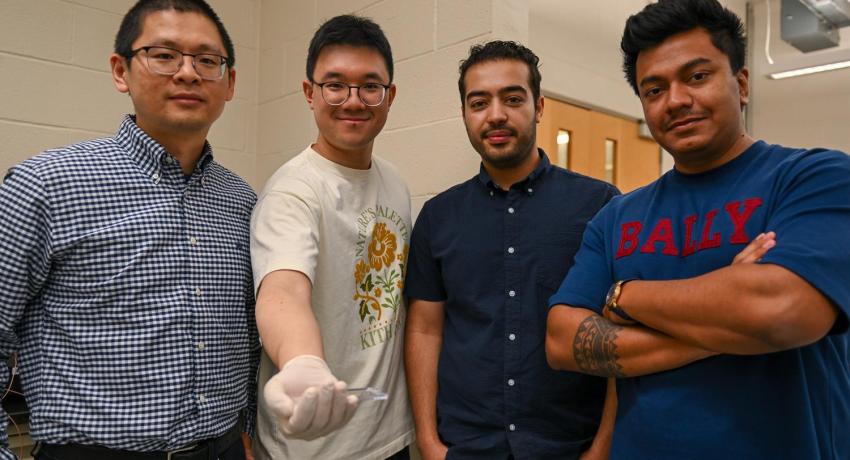

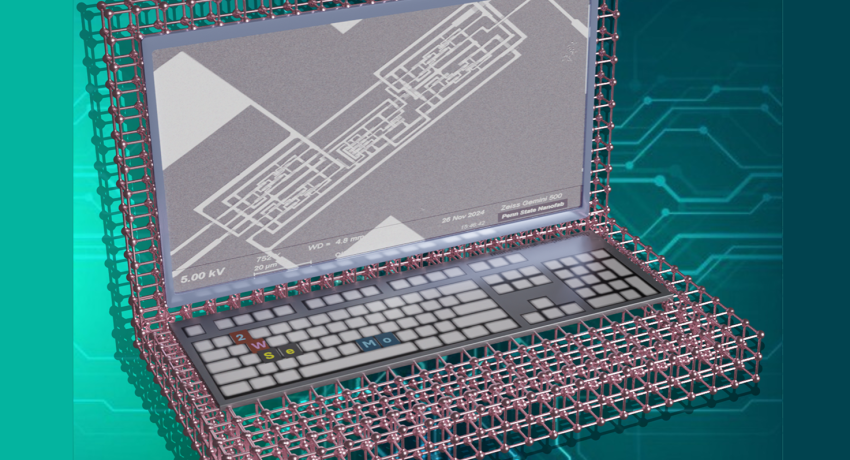

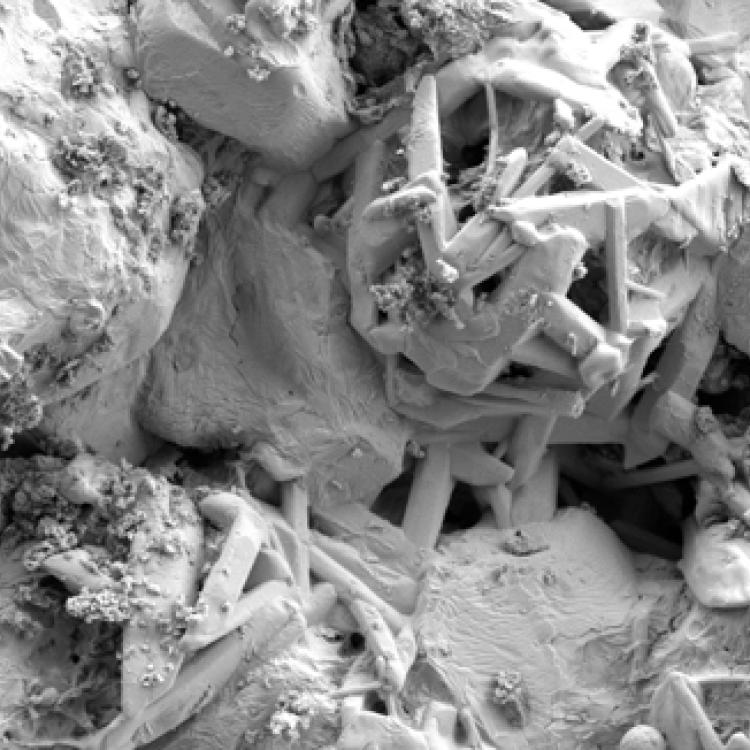

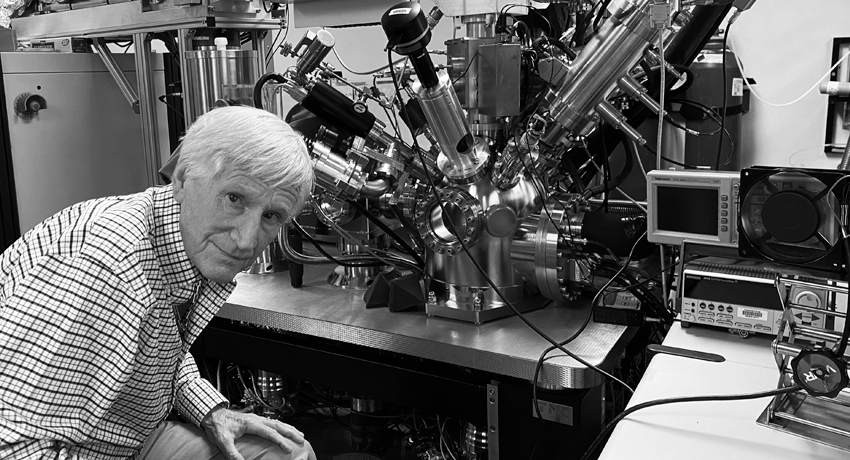

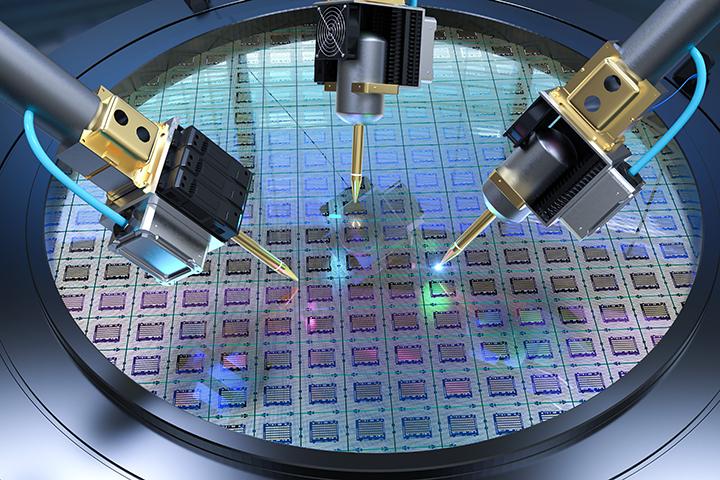

Focused on the development of two dimensional (2D) chalcogenides for applications in next generation electronics beyond silicon for digital circuits and flexible electronics.

Focused on the development of two dimensional (2D) chalcogenides for applications in next generation electronics beyond silicon for digital circuits and flexible electronics.