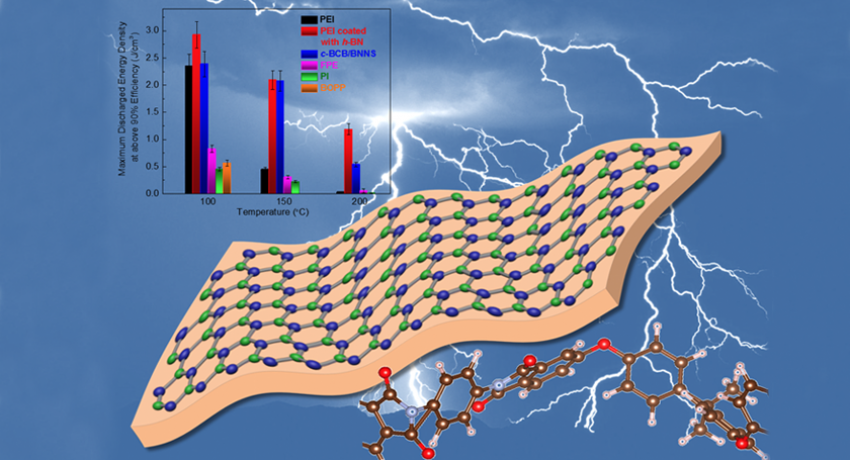

PEI coated with hexagonal boron nitride (hBN) nanosheets significantly outperforms competitive polymers at operating temperatures needed for electric vehicles and aerospace power applications. Credit: Feihua Liu/ Penn State

A new, lightweight composite material for energy storage in flexible electronics, electric vehicles and aerospace applications has been experimentally shown to store energy at operating temperatures well above current commercial polymers, according to a team of Penn State scientists. This polymer-based, ultrathin material can be produced using techniques already used in industry.

“This is part of a series of work we have done in our lab on high-temperature dielectrics for use in capacitors,” said Qing Wang, professor of materials science and engineering at Penn State. “Prior to this work we had developed a composite of boron nitride nanosheets and dielectric polymers, but realized there were significant problems with scaling that material up economically.”

Scalability – or making advanced materials in commercially relevant amounts for devices – has been the defining challenge for many of the new, two-dimensional materials being developed in academic labs.

“From a soft materials perspective, 2D materials are fascinating, but how to mass produce them is a question,” Wang said. “Plus, being able to combine them with polymeric materials is a key feature for future flexible electronics applications and electronic devices.”

To solve this problem, Wang’s lab collaborated with a group at Penn State working in two-dimensional crystals.

“This work was conceived in conversations between my graduate student, Amin Azizi, and Dr. Wang’s graduate student, Matthew Gadinski,” said Nasim Alem, assistant professor of materials science and engineering and a faculty member in Penn State’s Center for 2-Dimensional and Layered Materials. “This is the first robust experiment in which a soft polymeric material and a hard 2D crystalline material have come together to create a functioning dielectric device.”

Azizi, now a post-doc at UC Berkeley, and Gadinski, now a senior engineer at DOW Chemical, developed a technique using chemical vapor deposition (CVD) to make multilayer hexagonal boron nitride nanocrystal films and transfer the films to both sides of a polyetherimide (PEI) film. They next bonded the films together using pressure into a three-layer sandwich structure. In a result that was surprising to the researchers, pressure alone, without any chemical bonding, was enough to make a free-standing film strong enough to potentially be manufactured in a high-throughput roll-to-roll process.

The results were reported in a recent issue of the journal Advanced Materials in a paper titled “High-performance Polymers Sandwiched with Chemical Vapor Deposited Hexagonal Boron Nitrides as Scalable High-Temperature Dielectric Materials.”

Read the full news story here:

http://news.psu.edu/story/475980/2017/07/31/research/energy-storage-solution-...