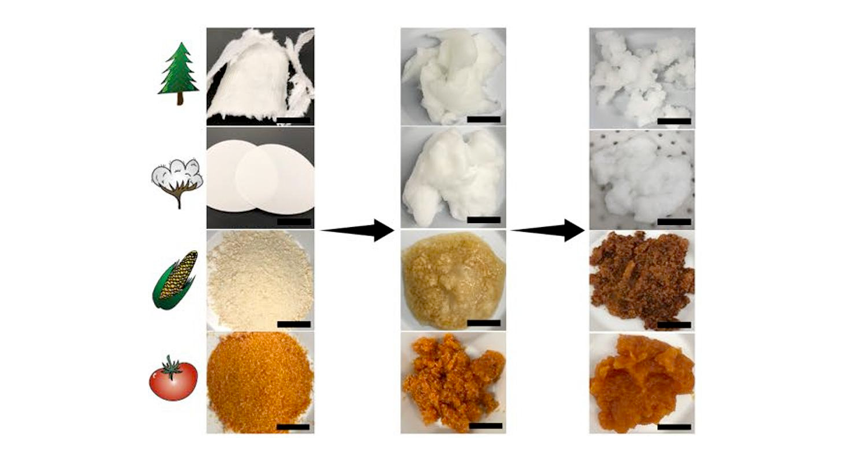

After soaking the materials in water (as shown in middle column), Penn State researchers chemically reacted shredded wood pulp, cotton paper and ground corncob and tomato peels to convert them into microproducts, nanoparticles and solubilized biopolymers (third column). Adding these microproducts or nanoparticles to solutions containing the rare earth element neodymium triggered the separation process, allowing for capture of the neodymium. Credit: Sheikhi Research Group. All Rights Reserved.

By Mariah Chuprinski

What do corncobs and tomato peels have to do with electronics? They both can be used to salvage valuable rare earth elements, like neodymium, from electronic waste. Penn State researchers used micro- and nanoparticles created from the organic materials to capture rare earth elements from aqueous solutions.

Their findings, available online now, will also be published in the November issue of Chemical Engineering Journal.

“Waste products like corncobs, wood pulp, cotton and tomato peels often end up in landfills or in compost,” said corresponding author Amir Sheikhi, assistant professor of chemical engineering. “We wanted to transform these waste products into micro- or nanoscale particles capable of extracting rare earth elements from electronic waste.”

Rare earth metals are used to manufacture strong magnets used in motors for electric and hybrid cars, loudspeakers, headphones, computers, wind turbines, TV screens and more. However, mining these metals proves challenging and environmentally costly, according to Sheikhi, as large land areas are required to mine even small amounts of the metals. Instead, efforts have turned to recycling the metals from electronic waste items like old computers or circuit boards.

The challenge lies in efficiently separating the metals from refuse, Sheikhi said.

“Using the organic materials as a platform, we created highly functional micro- and nanoparticles that can attach to metals like neodymium and separate them from the fluid that surrounds them,” Sheikhi said. “Via electrostatic interactions, the negatively-charged micro- and nano-scale materials bind to positively-charged neodymium ions, separating them.”

To prepare the experiment, Sheikhi’s team ground up tomato peels and corncobs and cut wood pulp and cotton paper into small, thin pieces and soaked them in water. Then, they chemically reacted these materials in a controlled fashion to disintegrate them into three distinct fractions of functional materials: microproducts, nanoparticles and solubilized biopolymers. Adding the microproducts or nanoparticles to neodymium solutions triggered the separation process, resulting in the capture of neodymium samples.

In this most recent paper, Sheikhi improved upon the separation process demonstrated in previous work and extracted larger sample sizes of neodymium from less concentrated solutions.

Sheikhi plans to extend his separation mechanism into real-world scenarios and partner with interested industries to further test the process.

“In the near future, we want to test our process on realistic industrial samples,” Sheikhi said.

“We also hope to tune the selectivity of the materials toward other rare earth elements and precious metals, like gold and silver, to be able to separate those from waste products as well.”

In addition to Sheikhi, Mica Pitcher, Penn State doctoral student in chemistry and first author on the paper; Breanna Huntington, Penn State undergraduate student in agricultural and biological engineering; and Juliana Dominick, Penn State undergraduate student in biomedical engineering, contributed to the paper.

Penn State supported this work.