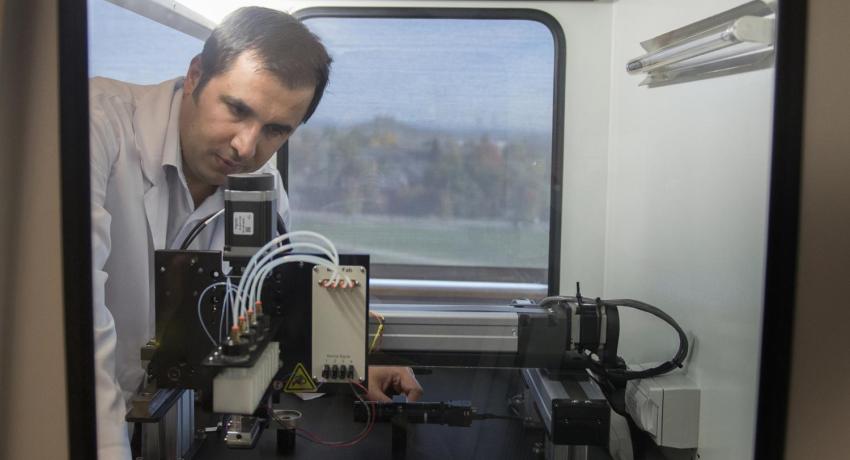

Ibrahim Ozbolat, professor of engineering science and mechanics, biomedical engineering and neurosurgery at Penn State, leads a lab that specializes in 3D printing to create a range of tissues for use in human health. Credit: Patrick Mansell/Penn State Creative Commons

By Adrienne Berard

Developing technology to quickly and efficiently bioprint human tissues at scale is the goal of a new project led by Penn State researchers. When fully developed, the technology will be the first to enable the fabrication of scalable, native tissues such as bones, tracheas and organs.

The National Institute of Biomedical Imaging and Engineering at the National Institute of Health has awarded over $2 million in support of the project, led by Ibrahim T. Ozbolat, professor of engineering science and mechanics, biomedical engineering, and neurosurgery at Penn State.

“This will be a platform technology, which can be used for multiple purposes,” said Ozbolat. “It could be used for implantation, inserting tissue directly into the body, or it can bioprint model organs for research like drug development and disease modeling. The ultimate use is for healthcare applications, but it can cover a broad range of functions.”

Ozbolat’s lab has spent years developing a process to bioprint cellular aggregates like spheroids, three-dimensional clusters of cells that mimic the biology of tissues and tumors. In 2019, the research team was awarded funding from NSF to explore the fundamentals of the technique. Now the team will use funding from NIH to scale up the process and quickly bioprint spheroids into desired patterns for the fabrication of tissues with cell densities similar what is found in nature.

“This technology, once fully developed, can be applied for the fabrication of a variety of human tissues,” said co-principal investigator Elias Rizk, a professor of neurosurgery at Penn State College of Medicine. “It could be cardiac tissue or lung tissue. It could be skin or even bone, which is tissue. This technology could repair bone in a rapid manner, even in sensitive places like the skull.”

The project is the result of an interdisciplinary collaboration between engineers at Penn State and physicians at Penn State College of Medicine. The team includes experts in bioprinting, instrument development, biomaterials, craniofacial surgery, and bone and lung tissue engineering.

The technology, which the team has titled “high-throughput spheroid (HTS) bioprinting,” will have the ability to bioprint multiple spheroids in a range of sizes all at once, according to the researchers. Once developed, it will have high accuracy in all three dimensions and will operate at an unprecedented speed. The technology will be versatile enough that it can print complex structures onto the surface of gel substrates for research purposes or in a scaffold-free manner for the scalable fabrication of tissues.

“We are already printing these tissue ‘bricks’ with the highest throughput in the literature,” Ozbolat said. “That's the most significant and unique part of this technology. It’s truly amazing. If we can do it quickly, at scale, then it could fundamentally change the field of medicine.”