Work on 3D printing concrete structures for housing at Penn State started in the Additive Construction Lab, a joint effort between the College of Arts and Architecture and the College of Engineering. Credit: Additive Construction Lab. All Rights Reserved.

Alaska needs an estimated 27,500 new housing units over the next 10 years to alleviate overcrowding and unsanitary conditions, according to the Alaska Housing Foundation Corporation. An interdisciplinary team of Penn State researchers led by José Pinto Duarte, Stuckeman Chair in Design Innovation and director of the Stuckeman Center for Design Computing (SCDC) in the College of Arts and Architecture’s Stuckeman School, is looking to alleviate some of that stress with a $376,000 U.S. Department of Housing and Urban Development (HUD) grant. The award is part of a larger $1.6 million matching grant program funded by HUD, the Denali Commission, the Alaska Housing Finance Corporation, the city of Nome, Alaska, and the Rasmuson Foundation, to demonstrate the viability of 3D printing affordable concrete homes in rural Alaska.

“These federal and state agencies, led by HUD, are interested in using innovative technology to provide people with affordable housing,” Duarte said.

HUD’s interests align with the SCDC’s mission “to integrate digital technology into design and construction processes,” according to Duarte.

When he came to Penn State in 2016, Duarte started researching concrete 3D-printing technology that would eventually lead to the establishment of the Additive Construction Laboratory (AddConLab). The lab is a joint effort between the College of Arts and Architecture and the College of Engineering.

HUD issued funding to the city of Nome, which then turned to the Xtreme Habitats Institute (XHI), an Alaska-based non-profit corporation with a mission to research, test and demonstrate new technologies that have the potential to improve living and working conditions in rural Alaska. XHI will work with AddConLab faculty, the Cold Climate Housing Research Center (CCHRC,) the National Renewable Energy Laboratory (NREL) and X-Hab 3D, a State College-based robotics and materials company co-founded by Duarte that has developed a mobile, expeditionary 3D concrete printing system that will be used to print the demonstration housing structures for the project. Three doctoral students — one in architecture and two in engineering — will also work on the structural aspects and material development of the project.

Sven Bilén, professor of engineering design, electrical engineering and aerospace engineering, and the lead of systems engineering at X-Hab 3D, and Shadi Nazarian, H. Ralph Hawkins, FAIA, Chair in Architecture at the University of Texas at Arlington and the lead for architectural design and advanced materials at X-Hab 3D, will also work on the project. They will be joined by Nate Watson, XHab 3D’s vice president of engineering and product and a Penn State College of Engineering alumnus with a master’s degree in additive manufacturing. Bilén will travel to Alaska to assess the performance of the mobile 3D printer and to assist with on-site logistics.

Ali Memari, professor and Bernard and Henrietta Hankin Chair in Residential Building Construction, will lead the structural team on the project, which will 3D print concrete wall specimens and, after adding steel reinforcing bars in selected cavities embedded in cast concrete, test the walls for flexural strength, which is resistance to bending under horizontal wind pressure.

The team will add rebars in the cells of the printed concrete and fill the cell with cast concrete to strengthen the wall in resisting the horizontal wind pressure. To show if the wall has enough capacity to resist the wind load, they will use the material and section properties of the concrete wall and equations that can predict the resistance of the wall to bending.

"The results of such tests can then be used for structural load resistance calculations," Memari said. These calculations will predict the wall's resistance to bending under pressure.

Due to Alaska’s frigid climate, the team will use a short window of time in the summer to print the materials. They said they hope to print the first structure in the summer of 2024, but the houses will not come without obstacles.

“As any technology that’s still evolving, it’s not perfect yet,” Duarte said. “That may slow down the construction or lead to making corrections or further adaptations to the design.”

Duarte cited challenges such as designing the house to meet the proper energy requirements and Nome’s isolated location, which could cause an increase in shipping costs and restrictions. The city’s permafrost soil melting in the summer may also cause an unstable foundation. The team needs to find a suitable area for the houses to sit upon and take all these factors into account when designing and building the houses.

“Warming air temperature causes coastal erosion or land loss and causes the permafrost to thaw and the infrastructure above it to fail,” said team member Ming Xiao, professor of civil and environmental engineering. “That has significantly affected people’s lives.”

The method of 3D printing offers benefits to the team. Because the team can print a structure in a matter of days or even hours, the construction cost is lower and using local materials can reduce the project’s carbon dioxide emissions.

“The project is of critical importance to the state of Alaska but has widespread implications as we try as a society to curb our CO2 emissions,” said Aleksandra Radlińska, associate professor of civil and environmental engineering and team member.

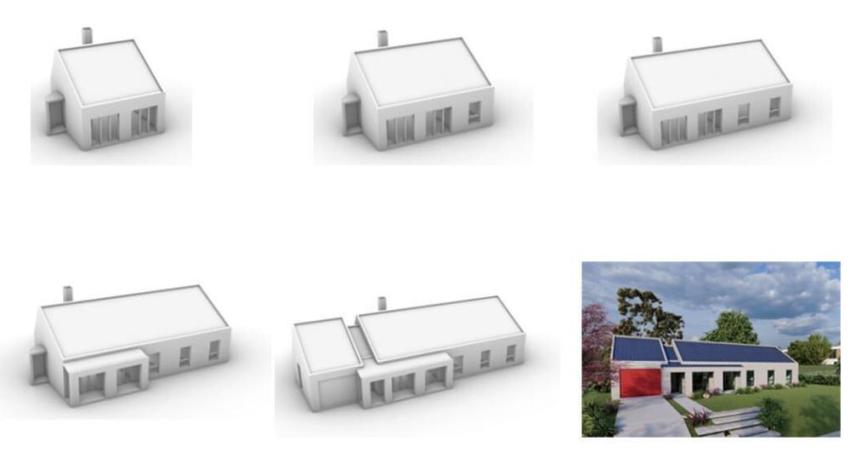

The design program the team is using makes the houses customizable for the needs of the families, and the concrete’s liquid form also makes it highly customizable.

“The possibility of deploying mass customizable structures in an environment like this is intriguing,” said team member Nathan Brown, assistant professor of architectural engineering.

The Penn State team prepared a questionnaire for residents of Nome to gather residents’ feedback on how they live and their expectations for the homes. A rule-based design system created by the team will generate diverse housing solutions that take a family’s needs into account by offering different options for kitchen sizes, bathroom and room numbers, relative locations and more. For the first house, the city of Nome will elect a family to inhabit it to assess the livability of the home. From there, the team can use the feedback to tweak the software platform that can generate housing solutions for effective, affordable homes for the city.

“We need to understand how people live, how they interact with each other and how the house is connected with the rest of the community,” Duarte said.

Duarte said the team hopes to build a housing complex of about 12 houses in Nome, and HUD expressed interest in using the technology to build about 400 new houses over a three-to-five- year period.

“I hope the project may lead to more projects like this in other states, including Pennsylvania and maybe beyond the United States,” Duarte said. “I strongly believe 3D printing technology at the construction scale can help overcome the shortage of affordable housing and improve the situation of disadvantaged communities.”

Graduate students assisting on the project are: Ali Baghi, architecture; Gonçalo Duarte, Ziyi Wang and Zhengyu Wu, architectural engineering; and Hanbin Cheng and Faisal Aljuwayhel, civil and environmental engineering.