Electrical Characterization includes many different techniques to evaluate ferroelectric, piezoelectric, dielectric and semiconductor materials and devices through a range of variables including time, temperature, frequency and voltage. Multiple instruments, test fixtures and ovens can be dynamically configured into measurement systems to achieve research objectives with many systems being completely automated. The following information is intended to convey the most common configurations and their limits. Extended capabilities often exist and should be discussed with staff.

Characteristic Types

- Ferroelectric

- Piezoelectric

- Pyroelectric

- Dielectric/ Insulator

- Semiconductor

Forms

- Free Standing Films

- Films on Substrates

- Bulk (Pellets)

- Devices

- Liquids (0.2 to 200GHz)

- Probe Stations

(Cryogenic • Hall Effect • Semi-Automated • Manual) - Semiconductor Parameter Analyzers

- Automated Data Collection Systems

- Impedance Analyzers

- Vector Network Analyzers

- Remnant Polarization and Strain Hysteresis Measurement

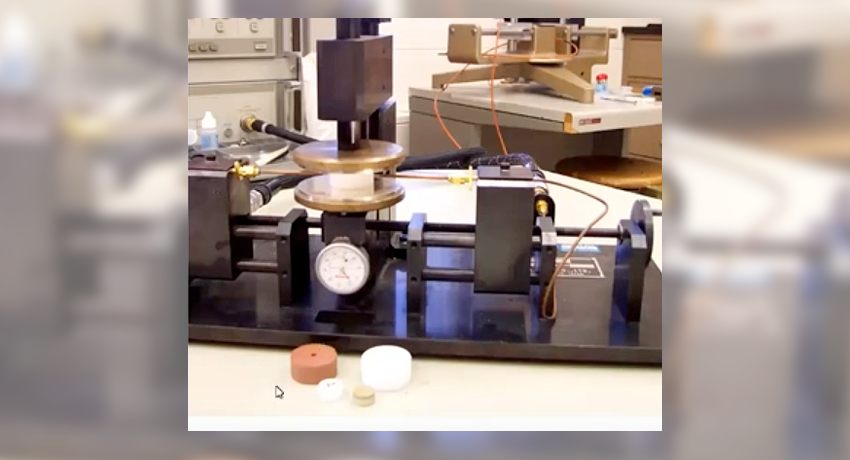

- d33 PiezoMeter

(pA Meters • Multimeters • Temperature Chambers) - Lock-in Amplifiers

- Elastic Moduli and Damping Measurement Equipment

- Thermally Stimulated Depolarization Current (TSDC)

- Highly Accelerated Lifetime Testing (HALT)

- Dielectric Breakdown

- Electrochemical Impedance Spectroscopy (EIS)

- Microwave / 5G Techniques

- Electrical Displacement & Strain

- Piezoelectric Constant d33 (direct or converse)

- Sample Poling

- Rayleigh & First Order Reversal Curve (FORC)

- Semiconductor Carrier Transport Analysis

- Van der Pauw & Hall Effect

- Conductivity/Resistivity (bulk & sheet)

- Reliability -IV (Current Voltage)

- CV (Capacitance Voltage)