Particle size significantly affects material properties such as chemical reactivity, bioavailability, dissolution and crystallization rates, stability in suspension, texture of the material, flow ability and handling, packing density and porosity, to name a few. Knowledge of particle size leads to better understanding of products and processes and helps to optimize efficiency of process to reduce costs.

Malvern Instruments

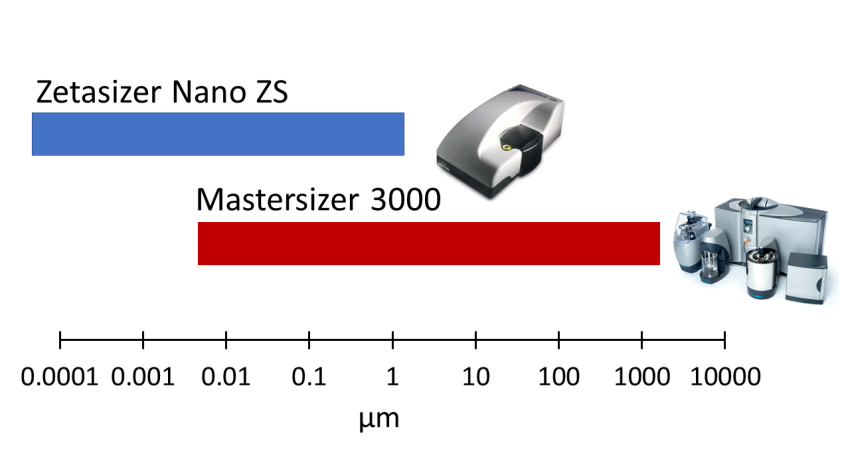

- Zetasizer Nano ZS

- Mastersizer 3000

Both of these instruments have the ability to measure and report particle size distribution of a sample.

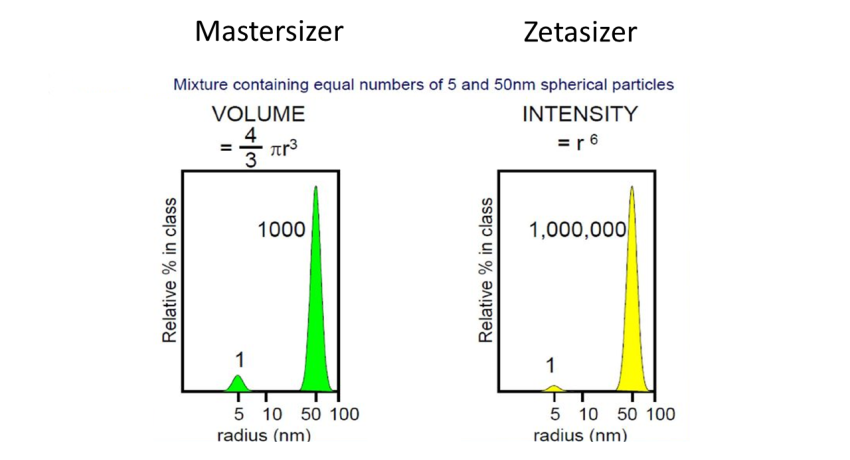

Particle size distribution can be represented in different ways with respect to the weighting of individual particles. The weighting mechanism will depend upon the measuring principle/technique being used. The most commonly used are number-weighted, volume-weighted and intensity weighted distributions.

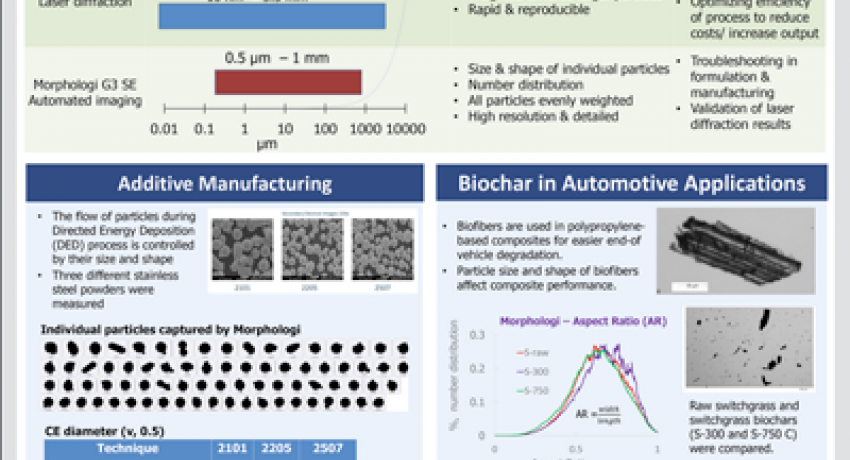

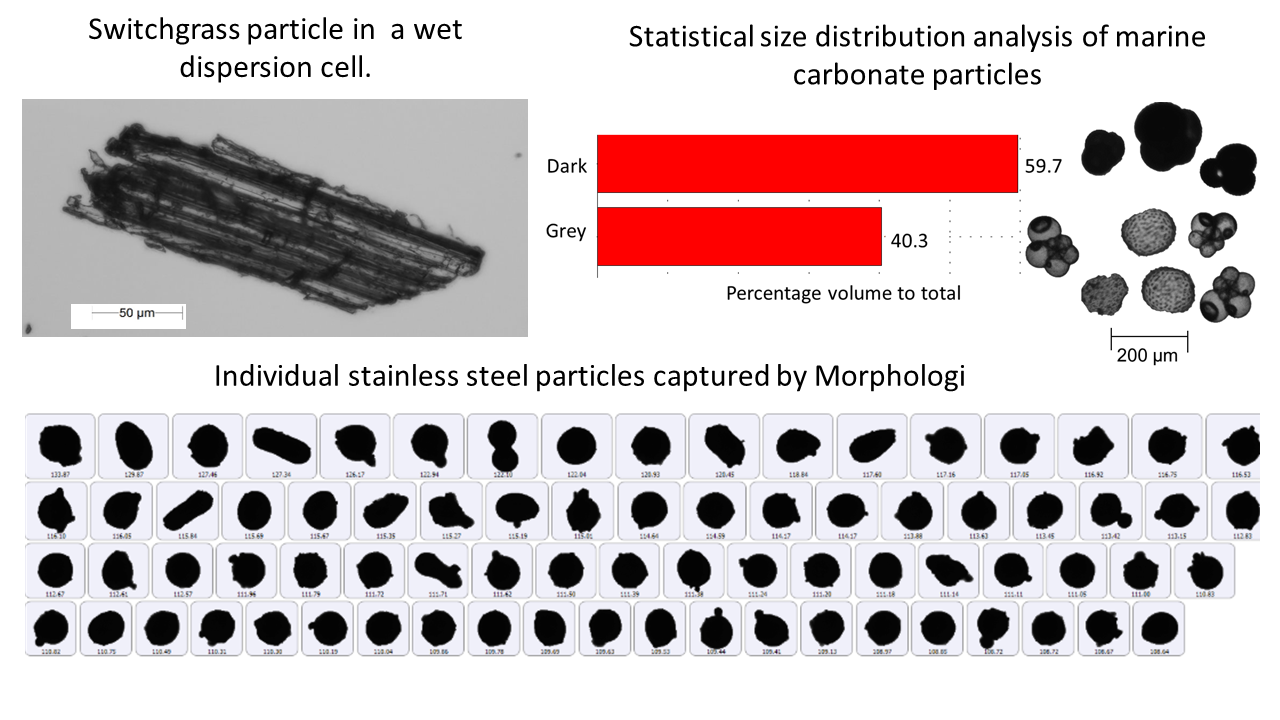

Overview of linking particle imaging and laser diffraction. Details include:

- Types of instruments and their measurement and purpose

- Additive manufacturing using three different stainless steel powders

- Biochar in automotive applications

| Instrument | Zetasizer Nano ZS | Mastersizer 3000 |

|---|---|---|

| Technique | Dynamic light scattering | Laser diffraction |

| Size distribution by | Intensity | Volume |

| Size range (diameter) | 0.3 nm – 10 μm | 10 nm – 3500 μm |

| Type of measurement |

|

|

| Specifications |

|

|

| Sample requirements |

|

|

| Application/Materials | Proteins, biological cells, polymers, micelles, vesicles, carbohydrates, nanoparticles, and gels | Ceramics, metals, biomaterials, soils and sediments, carbon materials, food products |

| More information | More Info | More Info |

Data obtained by the Morphologi automated imaging system.