MCL's thermal analysis suite of characterization capabilities include three techniques: Thermogravimetric Analysis (TGA), Differential Scanning Calorimetry (DSC), Combined TGA/DSC up to 1500C (SDT) and Evolved Gas Analysis (EGA) via a TGA coupled to a Mass Spectrometer (TGA-MS). The data obtained by these techniques and applications examples are shown in the table below.

| Technique | Data Obtained | Applications |

|---|---|---|

| TGA | Weight loss/gain in mg and % Temperature of weight change transition. |

Thermal and Oxidative Stability of Materials: - Composition of Multi-component Systems • The Effect of Reactive or Corrosive Atmospheres on Materials • Moisture and Volatiles Content of Materials |

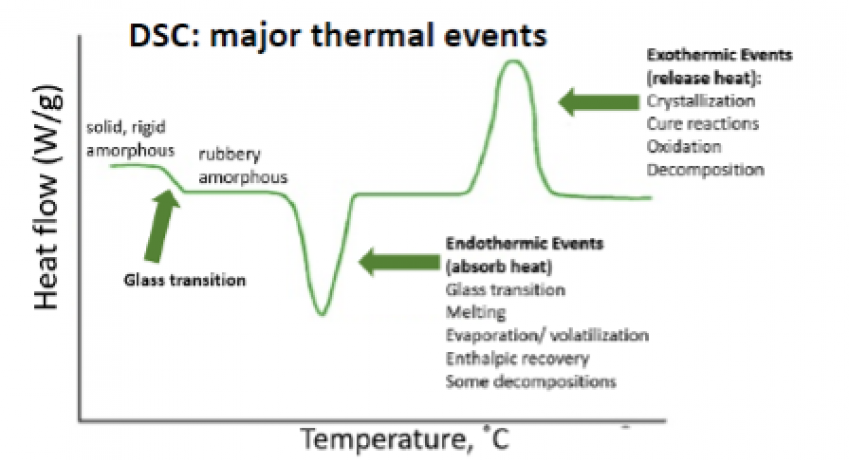

| DSC | Heat flow changes with temperature. | Melting and Crystallization temperatures: - Glass transition temperature (amorphous materials) • “Cold” crystallization • Heat capacity • Cure kinetics • Crystalline content |

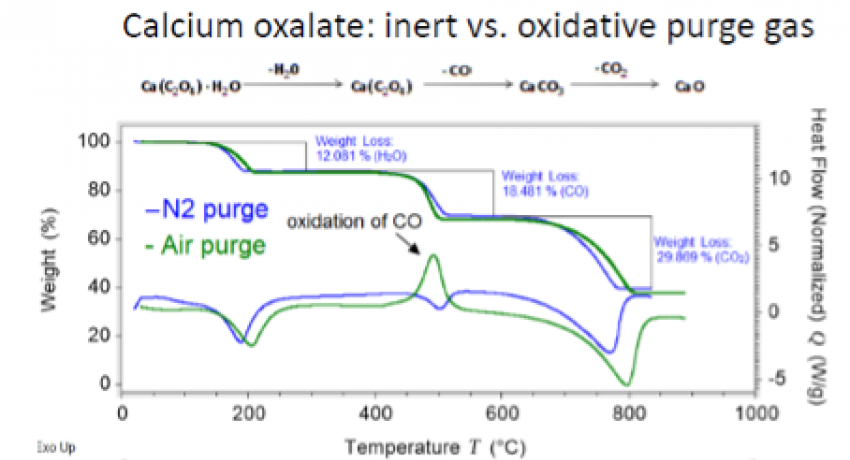

| SDT | Combined Heat flow and weight loss/gain as a function of temperature. | Same as TGA and DSC with TGA capabilities up to 1,500°C and heat flow capabilities from 200 to 1,500°C |

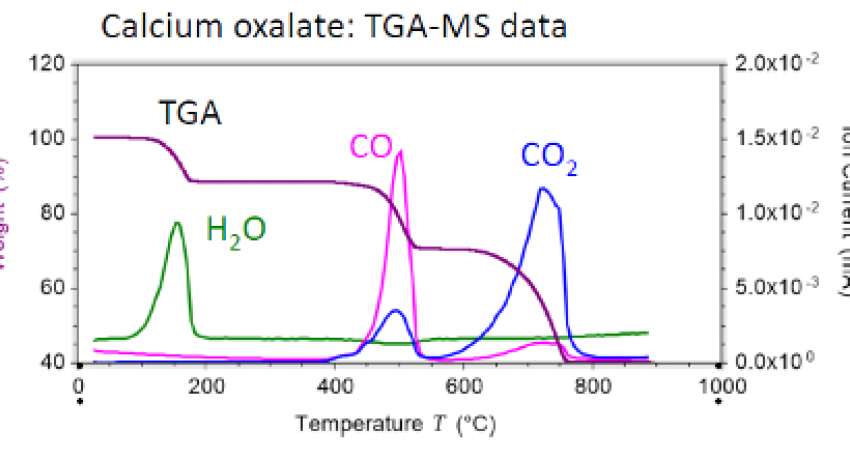

| TGA-MS | Evolved Gas Analysis: - Composition of gasses (m/z) evolved as temperature increases in a TGA. |

Identification of individual degradation products, residual solvents and contamination: - By-products analysis - Reaction Elucidation, stoichiometry |

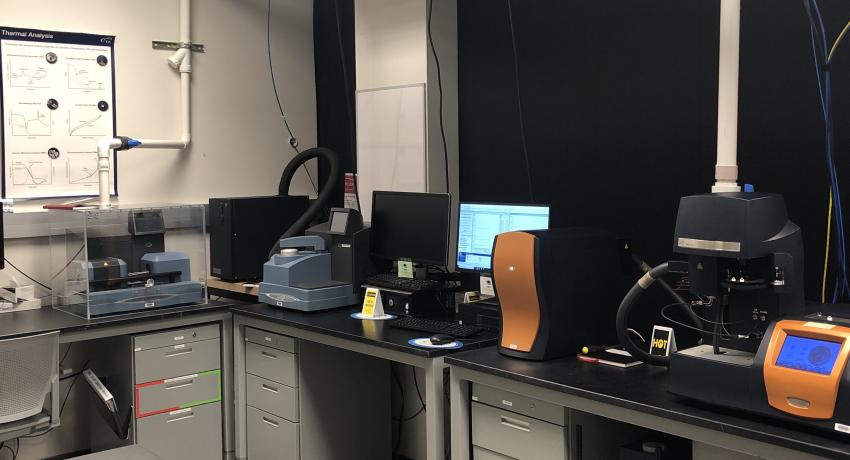

The Thermal Lab Suite

Typical DSC signals.

Combined TGA (top) and DSC (bottom) signals.

Combined TGA and EGA signals.

The following thermal instruments are available at MCL:

- TGA: Discovery TGA 550 with autoloader (TA Instruments) RT-1,000

- DSC: Discovery 2500 with autoloader (TA Instruments) -110-400°C

- SDT: SDT 650 with autoloader (TA Instruments) RT-1,500°C

- TGA MS: Discovery TGA 5500 coupled with Discovery MS (Ta Instruments) RT-1,000°C

| Instrument | TGA 550 | Discovery TGA-MS | TA 2500 DSC | SDT 650 |

|---|---|---|---|---|

| Technique | TGA | TGA and EGA | Dedicated DSC | Simultaneous TGA and DSC |

| Temp. Range (°C) | 25-1,000°C | 25 to 1,000°C | 25-1,000°C | 25 to 1,550°C |

| Sample Crucible Type | Platinum | Alumina (250) Platinum (100) Aluminum (80) |

Aluminum; T-zero hermetic and non-hermetic | Alumina (85) Platinum (85) |

| Typical Sample Size (mg) | 1-100 | 1-100 | 1-10 | 1-10 |

| Additional Features | Evolved gas atomic mass range 1-300 amu |

Modulated DSC Capability |