- ASAP 2420 Automated Surface Area and Porosimetry System has 12 sample degas ports and 6 measurements ports.

- Autopore V Mercury porosimeter has four low pressure ports and two high pressure which measure up to 60,000 psi.

Note: ASAP 2420 and Mercury porosimeter are staff-only operated equipment.

The summary of these instruments is outlined in the table below.

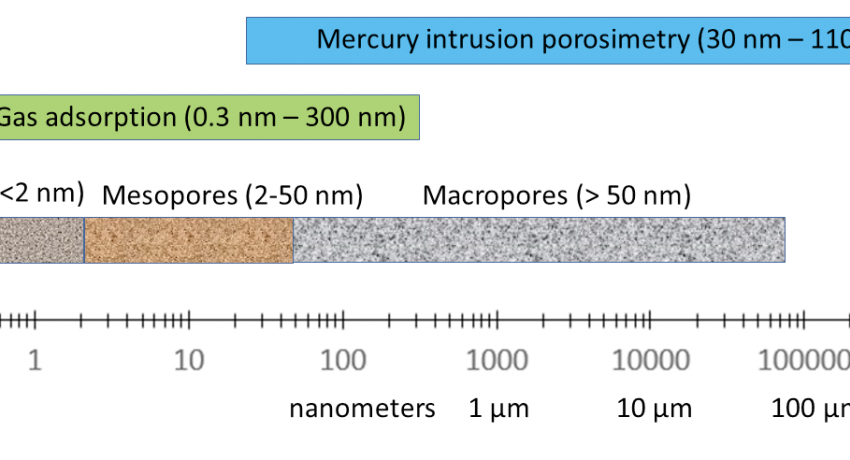

Range of Pore Size

Range of pore size (diameters) typically measured by gas adsorption and mercury intrusion porosimetry.

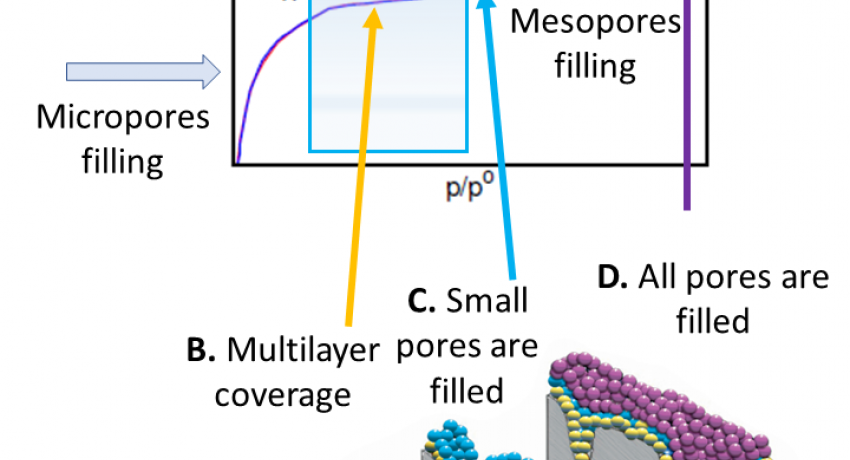

Gas Adsorption Curve

Gas adsorption isotherm illustrates gas uptake quantity as a function of pressure at a constant temperature.

Surface area and porosimetry include:

- Ceramic materials

- Activated carbons and carbon black

- Paints and coatings

- Catalysts, nanotubes

- Electronic devices

- Fuel cells

- Clays, minerals, soils

| Instrument | ASAP2420 | Autopore V |

|---|---|---|

| Technique | Gas Adsorption | Mercury Porosimetry |

| Data rovided | Pore volume, pore area material surface area |

Pore volume, pore area material density, percent porosity |

| Pore Size Range (diameter) | 0.3 nm to 300 nm | 30 nm to 1100 μm |

| Specifications |

|

|

| Sample Requirements/restrictions |

|

|

| Measurement Duration |

|

|

| More information | More Info: ASAP-2420 | More Info: AutoPore-V |