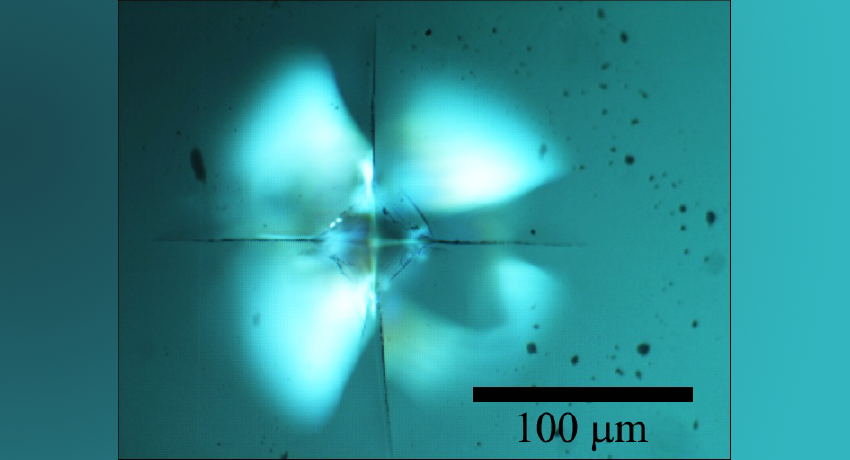

The nanoindenter is designed to measure the mechanical properties of surfaces on a submicroscopic scale. The indenter takes a small diamond probe, which is shaped as either a pyramid or a sphere and pushes the diamond tip into the surface of the material being tested. The depth of indentation can range from nanometer to a maximum of 4 microns. By measuring the force required to push the diamond tip into the material compared to the depth of the indentation, the instrument can determine the hardness of the sample. Seeing to what degree the material returns to its previous shape determines its elastic modulus - the stiffness of its atomic bonds.

Bruker Hysitron TI-980

Sample Requirements/Specifications

- 1D normal force and 1D nanoDMA transducer assemblies.

- Samples must be smooth on both front and backside. Backside polish only needs to be good enough to hold vacuum or glued to metal disk for mounting on stage.

- Sample must be flat (less than 1 degree of tilt when loaded on stage).

- Sample Size: less than 10cm laterally, less than 4cm tall.

- Sample roughness will depend on indentation depth, less than 50nm is required.

- Maximum force is 10mN, maximum displacement in Z is 4μm.

- 1D Standard Nanoindentation.

- XPM - Accelerated Property Mapping.

- nanoDMA III Dynamic Nanoindentation.

- In-situ SPM Imaging.

| Z-axis | X-axis | |

| Maximum Force | 10 mN | 2 mN |

| Maximum Displacement | 4μm | 15μm |

| Load Noise Floor | 20 nN | 3.5 μN |

| Load Resolution | 1 nN | 50nN |

| Displacement Resolution | 0.006 nm | 0.02 nm |

| Displacement Noise Floor | 0.1 nm | 2 nm |

| Thermal Drift | Less tank 0.05 nm/sec | Less than 0.05 nm/sec |