Dry etching is a technique of transferring a pattern into a material using reactive gases. Typically this process involves generating a plasma in a process reactor using RF energy to ionize the reactive gases. Plasmas are very complex and have numerous different reactions happening in the plasma simultaneously. These reactions form ions, neutrals, and radicals in the plasma that are then accelerated to the surface of the material by an electric field. The electric field is formed between the plasma and the material to be etched. Dry etching is a more complex technique that may or may not have good selectivity between different materials which can be a drawback. However, the major advantage is that dry etching is typically very anisotropic in nature which allows for very reproducible etch characteristics.

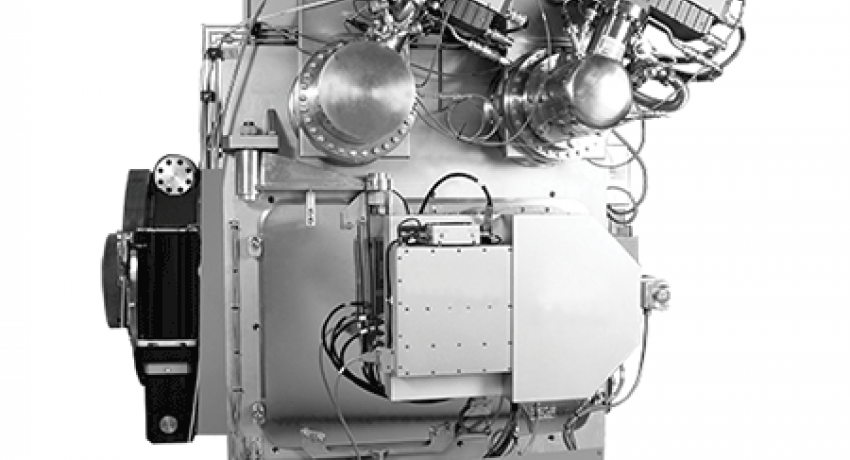

The nanofab has a many dry etching systems available for use. Together, the systems make it possible to etch a wide variety of materials with the desired features sizes, aspect ratio and depths required. Contact our staff for assistance in determining what tools would be best for your process.