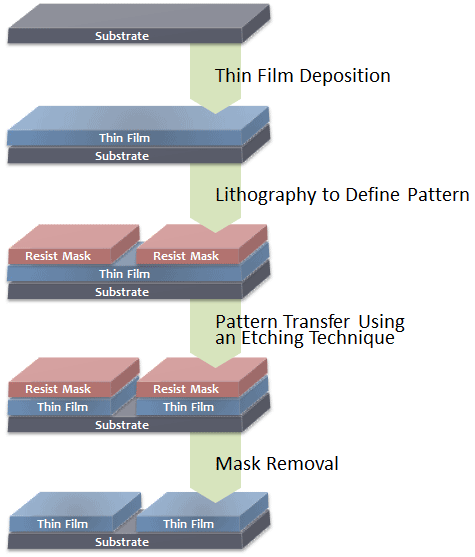

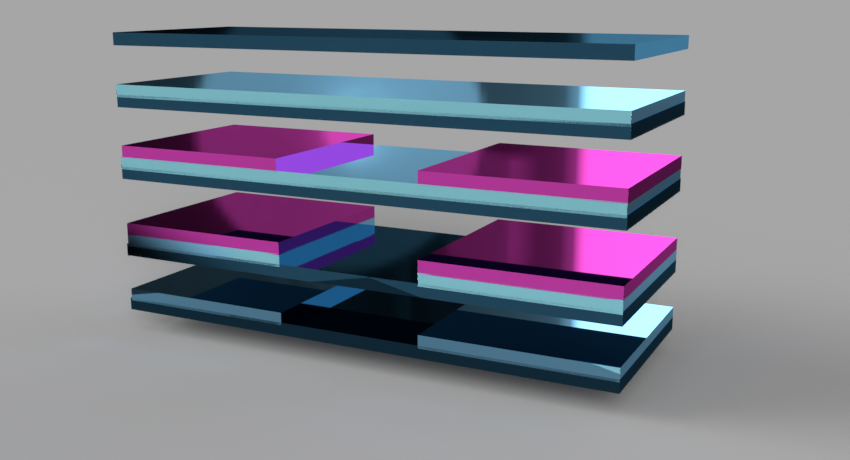

Etching is a process for transfering a pattern into a material. The etching process is accomplished by using a variety of different techniques. The two most common techniques for etching a pattern into a material are Wet Etching and Dry Etching. Each of these techniques has its advantages and disadvantages and one must decide which technique best suits their process requirements. Our staff are experts at guiding users through this the process of deciding which technique is optimal for their process.

Wet Etching

Wet etching is a technique for transferring a pattern into a material using liquid chemicals. Wet etching using liquid chemicals usually is described by an oxidation / reduction reaction also commonly referred to as a Redox reaction. Navigate to the Wet Chemical Etch sub-menu item at the right of the page.

Dry Etching

Dry etching is a technique of transferring a pattern into a material using reactive gases. Typically this process involves generating a plasma in a process reactor using RF (radio frequency) energy to ionize the reactive gases. Plasmas are very complex and have numerous different reactions happening in the plasma simultaneously. These reactions form ions, neutrals, and radicals in the plasma that are then accelerated to the surface of the material by an electric field. The electric field is formed between the plasma and the material to be etched. Dry etching is a more complex technique that may or may not have good selectivity between different materials, which can be a drawback. However, the major advantage is that dry etching is typically very anisotropic in nature which allows for very reproducible etch characteristics. Navigate to the Dry Etch sub-menu item at the right of the page.

Vapor Etching

Vapor etching is another type of dry etch process. In vapor etching the reactive gas that is chosen will spontaneously react with a material in the vapor phase without needing to generate a plasma. An example of vapor etching is the etching of Si using XeF2 gas for MEM's (micro-electro-mechanical systems)devices. Navigate to the vapor etching tab above for more information.