Instrument DOI: 10.60551/nbxg-q866

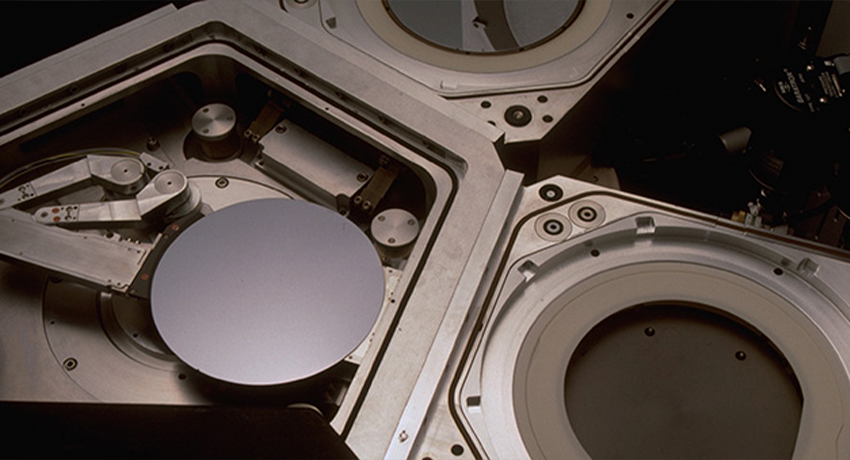

Applied Precision 5000 is the original Applied Materials cluster tool and one of the industry’s first single-wafer, multi-chamber platforms. Image Courtesy: Applied Materials

Applied Materials P-5000 PECVD Cluster Tool

The Applied Materials P-5000 is a four Chamber cluster tool capable of handling small pieces through 200mm (8 inch) wafers. Three of the four chambers are dedicated to Plasma Enhanced Chemical Vapor Deposition (PECVD).

The fourth chamber on the cluster tool is a Magnetically Enhanced Reactive Ion Etch (MERIE) used for etching silicon oxide, silicon nitride and some polymers.

| All CVD Chambers | Materials Deposited by Chamber |

|---|---|

|

|

The system can be run in either manual or automatic mode depending on the number of samples being run.

| Chamber A (liquid source oxides and nitride barriers) | Chamber B (silane based oxides and nitrides) | Chamber D (amorphous silicon and germanium) |

|---|---|---|

|

|

|