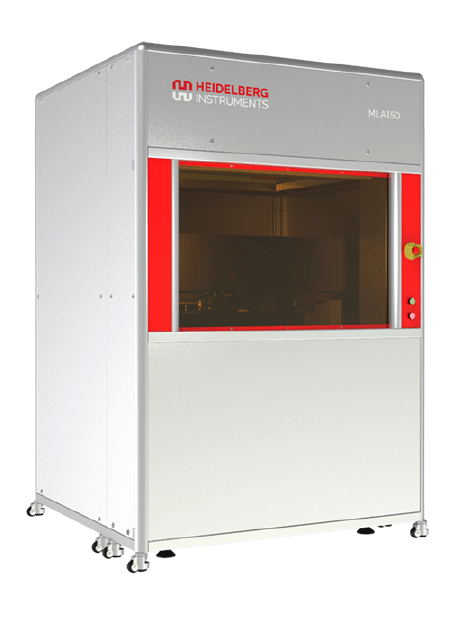

Heidelberg MLA 150 Direct Write Exposure Tool

Exposes patterns directly without prior fabrication of a mask resulting in significantly shorter prototyping cycles. The MLA 150 provides for flexible change of pattern, distortion compensation and other software corrections. The unique Draw-Mode allows the user to use the overhead camera to directly draw structures on the image, then directly write the structures.

Heidelberg DWL 66+

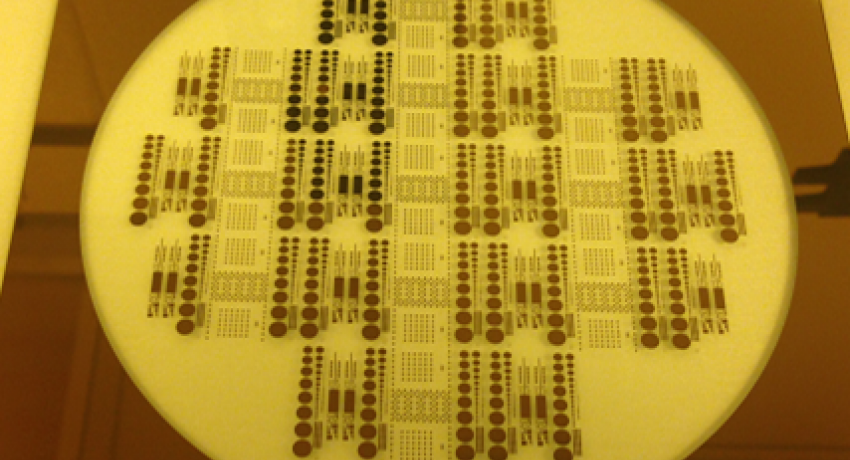

This laser writer is a high resolution pattern generator for mask making and direct writing on any flat surface coated with photoresist. The most recent upgrade adds grey scale patterning. Both laser writers can print down to 800 nm with overlay accuracy of 500 nm.

The laser writer is a high resolution pattern generator (PG) for mask making and direct writing on any flat surface coated with photoresist. A digital pattern file, created by the user with Computer Aided Design (CAD) software, directs the laser to areas on the substrate to expose the photoresist. This technique is often referred to as "maskless or direct-write" lithography.

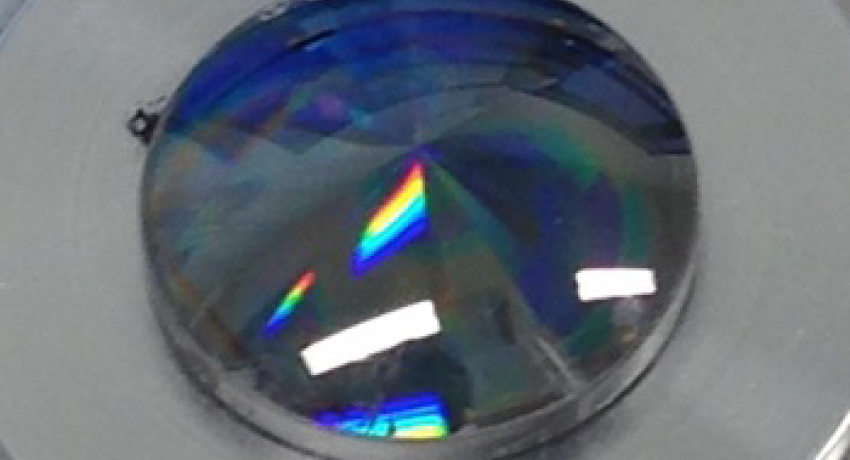

RAITH EBPG 5200

Electron beam lithography can achieve feature sizes of less than 10 nm.

It is a maskless or direct write technique that requires input of a CAD file.

This model has a unique Z-axis stage that adjusts to accommodate curved surfaces.

Equipment Details

7" mask

Raith EBPG 5200 can adjust to accommodate curved surfaces.

Instrument DOI: 10.60551/xb3n-h828

- Substrate sizes 3 mm x 3 mm to 150 mm x 150 mm

- Exposure area 150 mm x 150 mm

- Wavelength 405 nm

- Minimum feature size 600 nm

- Write-speed approximately 35 minutes for 100 mm full wafer

- Realtime autofocus

- Overview camera for inspection

- Front and backside alignment: 0.5 µm for global and 0.25 µm for local alignment errors

- Temperature controlled environmental chamber

- User-friendly software

- Substrates up to 9” x 9”

- Features down to 600 nm

- Address grid down to 10 nm

- Real-time autofocus

- Vector and raster exposure modes

- Exchangeable write modes

- Camera system for metrology and alignment

- Front to backside alignment

- Climate controlled chamber

- Multiple data input formats