A wireless, biodegradable sensor could offer doctors a way to monitor changes in brain chemistry without requiring a second operation to remove the implant, according to an international team of researchers.

In a minimally invasive procedure on mice, the researchers inserted a wireless, biodegradable device into the deep brain region of a mouse. The device collected data on levels of dopamine, an important neurotransmitter, and other properties of the brain, such as pH levels, temperature and electrophysiology before harmlessly dissolving back into the body.

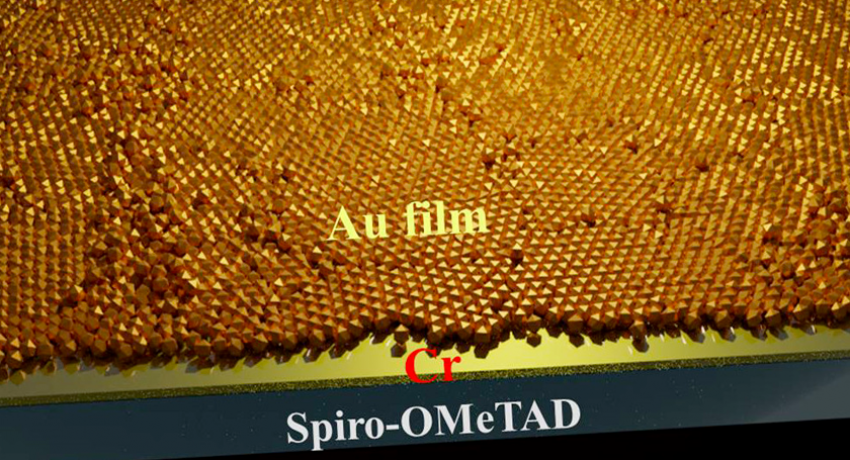

Developing new ultrathin metal electrodes has allowed researchers to create semitransparent perovskite solar cells that are highly efficient and can be coupled with traditional silicon cells to greatly boost the performance of both devices, said an international team of scientists. The research represents a step toward developing completely transparent solar cells.

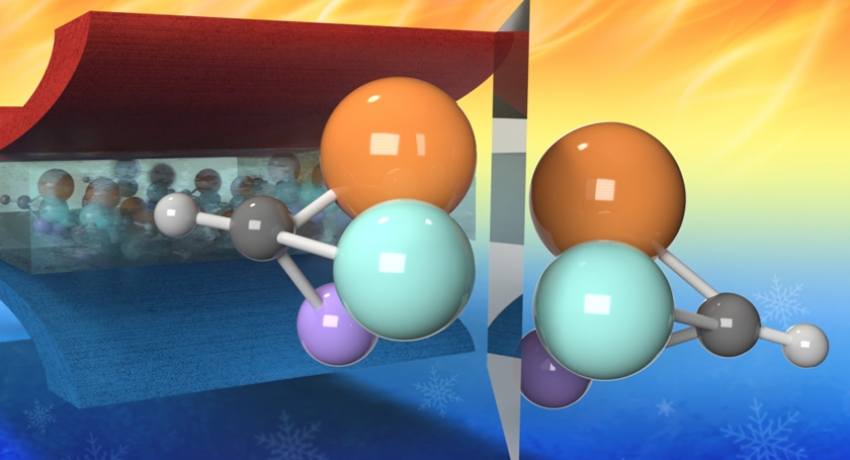

In energy storage capacitors, relaxors can deliver a much higher energy density than normal ferroelectrics, which have high ferroelectric loss that turns into waste heat. In addition, relaxors can generate larger strain under the applied electric fields and have a much better efficiency of energy conversion than normal ferroelectrics, which makes them preferred materials for actuators and sensors.

Penn State has a long history of discovery in ferroelectric materials. The first relaxor ferroelectric polymer was discovered by Penn State electrical engineering professor Qiming Zhang in 1998, when he used an electron beam to irradiate a ferroelectric polymer and found it had become a relaxor. Zhang along with Qing Wang also made seminal discoveries in the electrocaloric effect using relaxor polymers, which allows for solid state cooling without the use of noxious gases and uses much less energy than conventional refrigeration.

Teams of researchers led by Penn State provide new understanding of why synthetic two-dimensional materials often perform orders of magnitude worse than predicted, and how to improve their performance in future electronics, photonics, and memory storage applications.

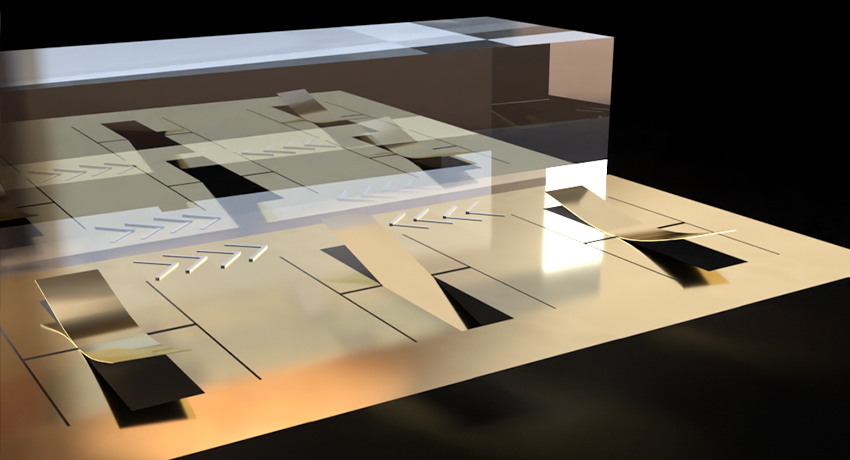

Two-dimensional materials are thin films only an atom or two thick. Researchers make 2D materials by the exfoliation method, which means peeling a slice of material off a larger bulk material, or by condensing a gas precursor onto a substrate. The former method provides a higher quality material, but is not useful for making devices. The second method is well established in industrial applications, but yields low performance 2D films.

In a paper published online in Scientific Reports, a Nature Group publication, researchers for the first time demonstrated why the quality of 2D materials grown by the chemical vapor deposition method have poor performance compared to their theoretical predictions.