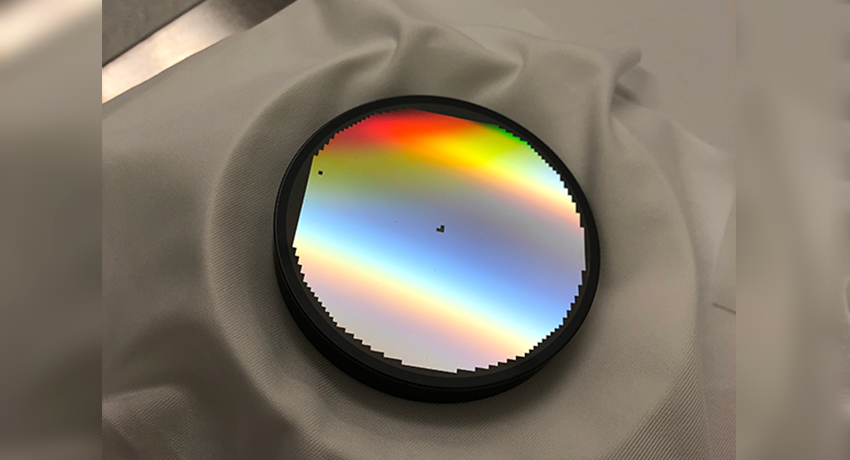

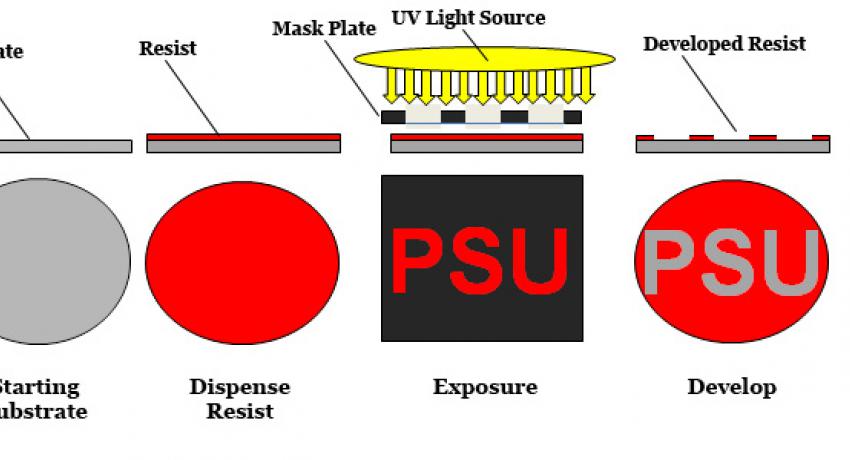

Lithography is a process of dispensing a photo sensitive polymer onto a substrate, exposing the coated substrate to a UV light source, and developing away the unwanted polymer. There are methods that utilize a physical plate to mask off unwanted light with predefined geometries, and methods that utilize a Computer Aided Design (CAD) drawing to expose the polymer with a laser or electron beam.

The polymer left on the substrate will serve as protection of the substrate for subsequent processing; etch, deposition, or implantation.

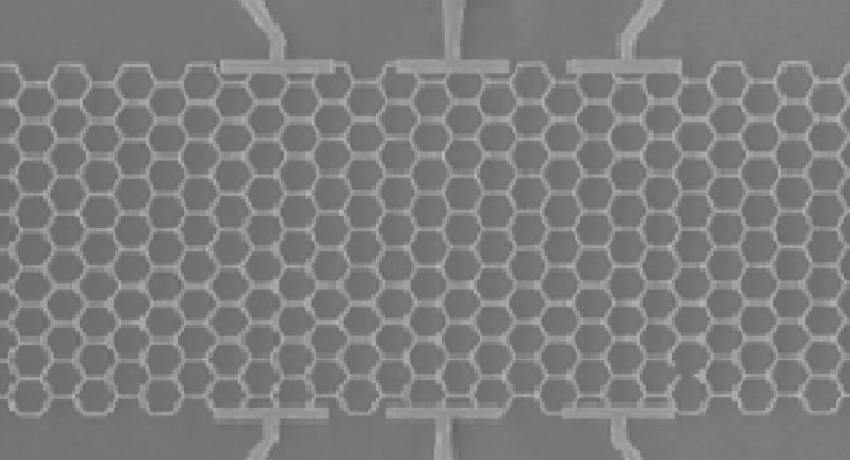

Lithography Techniques Available at Penn State