Lithography on curved samples and samples with very tall or deep features is a new area of development being undertaken by Penn State which opens up new possibilities in areas of optics, meta-materials and even electronics. It is comprised of three components.

Resist application

The typical spin casting of resist does not work well on curved surfaces so a special mist deposition tool has been acquired. It can controllably and reliably atomize and apply resist to curved surfaces.

Curved surface sample holders

Custom tooling required to handle thick and thin curved substrates.

Curved surface mapping

Currently, we pattern the surface with markers and characterize the heights via marker positions. Soon to be installed in the Nanofab will be a high-resolution surface curvature mapping microscope. This specialized tool will be used to map the curved surface at high resolution. The data is fed into the exposure tool.

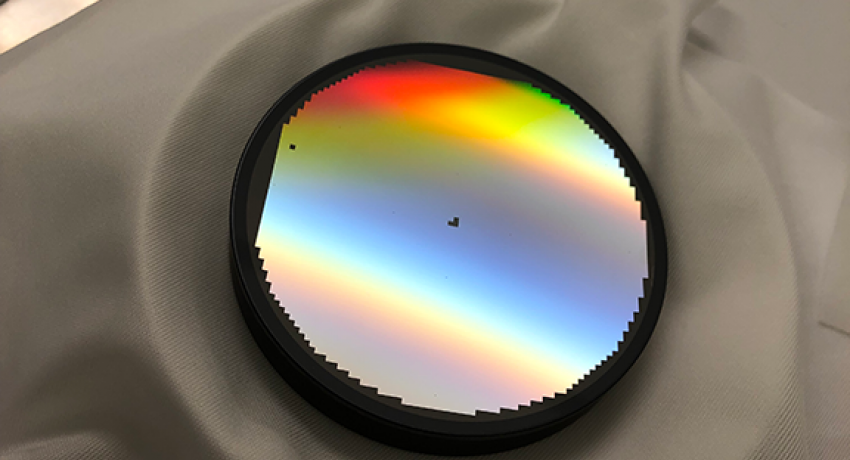

Optical lens pattern on curved surface using e-beam lithography. Image: Dr. Randy McEntaffer Group/Penn State

Curved surface sample holder.