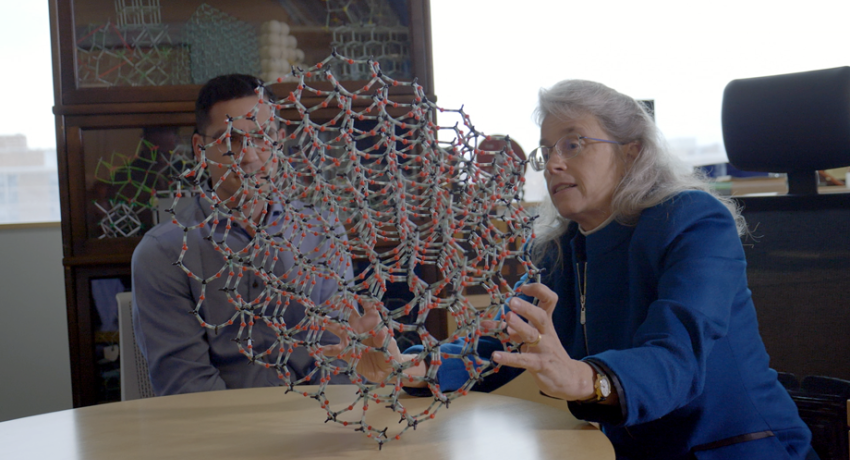

Trolier-McKinstry's semiconductor research is focused on lowering the energy needed for computing. Credit: Corey Beasley

While a lot of the focus on fighting climate change lands on things like gasoline vehicles and factory emissions, computers gobble up plenty of carbon-based energy on their own.

“If we could reduce the energy cost of computation, we could lower global warming,” said Susan Trolier-McKinstry, Evan Pugh University Professor, Steward S. Flaschen Professor of Ceramic Science and Engineering, and professor of electrical engineering. “Computing consumes a huge fraction of the overall energy budget of the world. It is currently above 10%. It is projected to go to 21%. If we could lower the energy costs for computing that would have enormous implications in terms of climate change.”

Trolier-McKinstry's semiconductor research is focused on doing just that – lowering the energy needed for computing. The way her work directly impacts semiconductors is around non-volatile memory, which is memory that can retain stored information even after a power source is removed. Current computers operate using what is known as the Von Neumann Architecture, first described in 1945 by mathematician and physicist John Von Neumann. This architecture’s key feature is that the memory chip and the processing chip are separate from each other.

“If you look at the current energy cost and time cost of computing, a very significant fraction of that cost is associated with the fact that the memory chip and the processing chip are physically separated in the system,” Trolier-McKinstry said. "That was a decision made by von Neumann decades ago, and it's served us really well to this point.” However, given the ubiquity of computers that will only increase, a better system is needed. "Today, the estimates are that up to 80% of the time cost and a considerable fraction of the energy costs for computing is associated with getting data back and forth between the memory and the processors or between processor units,” Trolier-McKinstry said.

Trolier-McKinstry is the director of a center at Penn State, the 3-Dimensional Ferroelectric Microelectronics (3DFeM), that is working to solve this issue.

“One of the main goals of this center is to change that paradigm to build the memory right on top of the processor unit so that you take away that extra energy and time burden,” Trolier-McKinstry said. “Using ferroelectrics also makes the memory non-volatile, so you do not have to keep rewriting it and then pay the energy costs every time associated with writing that memory. As a center, we are working on how to change the Von Neumann paradigm to enable low-energy cost computation.”

Trolier-McKinstry is also the director of the Center for Dielectrics and Piezoelectrics (CDP), a National Science Foundation Industry/University Cooperative Research Center. Both centers complement each other as a significant part of the semiconductor research effort at Penn State.

"To make a circuit function, you need both the active materials, which is what 3DFeM addresses, and all the passive materials, which is what CDP addresses,” Trolier-McKinstry said. “With the 3DFeM, we have many major U.S. players and several of the major international players in semiconductor production involved directly in the center. Through CDP, we have pretty much every multilayer ceramic capacitor supplier.”

These relationships between Penn State and industry are beneficial for the U.S. semiconductor industry, Trolier-McKinstry said.

“Using a different material set, Texas Instruments is currently one of the leaders in development of non-volatile memories,” she said. “We think we have better material, but they already have all the circuit designers. Because we interact with all the key players in manufacturing, we hope to see the manufacturing of these types of semiconductors occur in the U.S.”

This article originally appeared in the Fall 2022 issue of Focus on Materials.