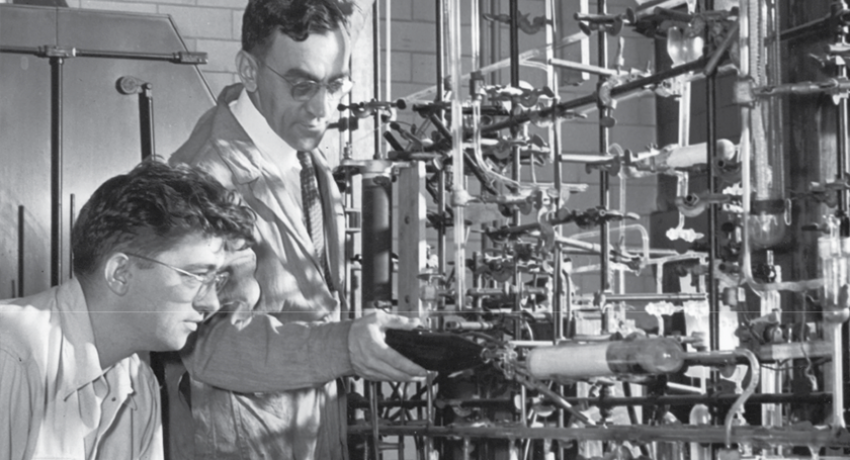

Master of Fluorine Science

Joseph H. Simons, Penn State professor of chemical engineering, discovered over 800 different fluorine-based materials. It was his development of the electrochemical fluorination (ECF), or Simons Process, that changed industrialization of fluorinated materials and chemistries. Prior to the development of this process, fluorination with fluorine, a highly reactive and toxic element, was a dangerous and wasteful process. Simons' fluorination idea, which entails electrolysis of an organic compound in a solution of hydrogen fluoride, proved to be much safer and more cost-effective.

The Simons Process was developed in the early 1940s, but no publications came out until after World War II due to its highly classified nature. This classification was because Simons' work led to his recruitment in 1940 to the Manhattan Project, as his

innovative fluorination technique enabled the formation of uranium hexaflouride (the hex phase). This was an essential step in the purification of uranium needed to build an atomic bomb.

Simon's groundbreaking technique was patented in 1948 by the Minnesota Mining and Manufacturing Company (3M). This was the result of 3M 1s partnership with Simons and Penn State that started in 1946.

Simons' fluorination method is now used in the production of high-performance materials, including artificial blood substitutes, surfactants, materials for polymers, refrigerants, magnets, and fluorochemicals for the electronics industry. Different combinations of electrode chemistries and fluorine molecules are used under different voltages to drive the process.