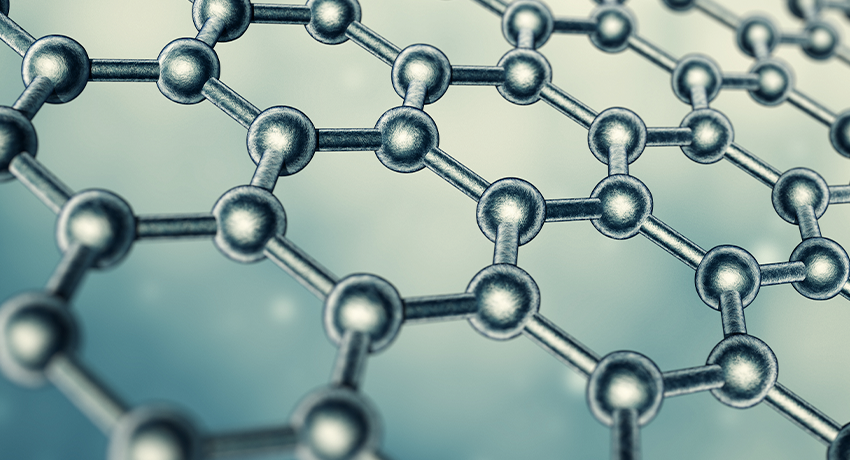

Materials research is linked to virtually every field of science and engineering. The discovery and development of new materials enables advances across diverse technologies, from computer chips to consumer electronics to building materials, energy, and transportation. Penn State researchers contribute to economic progress by developing advanced materials for new technologies, by lowering the cost and enhancing the performance of more established technologies.

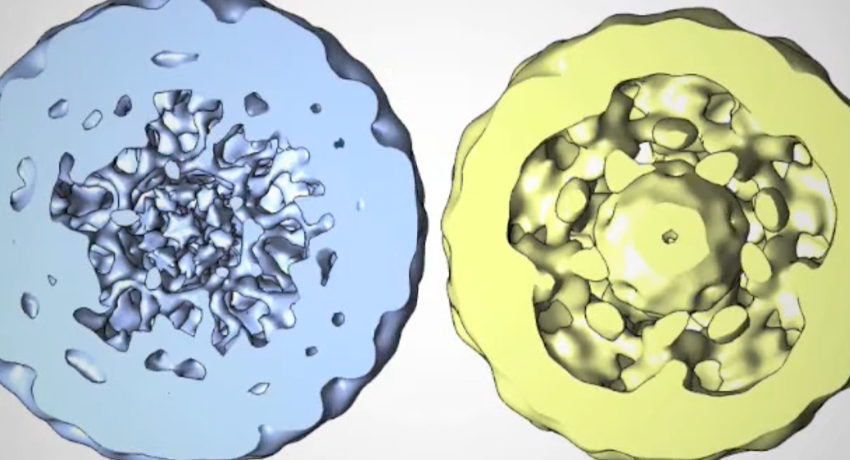

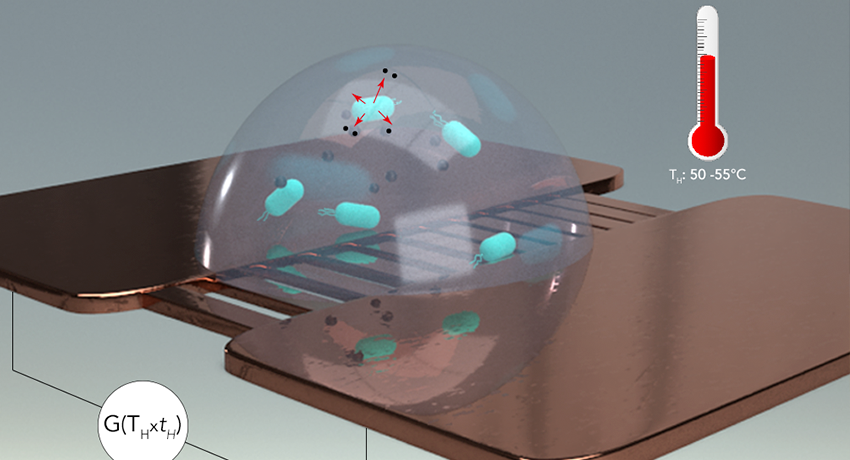

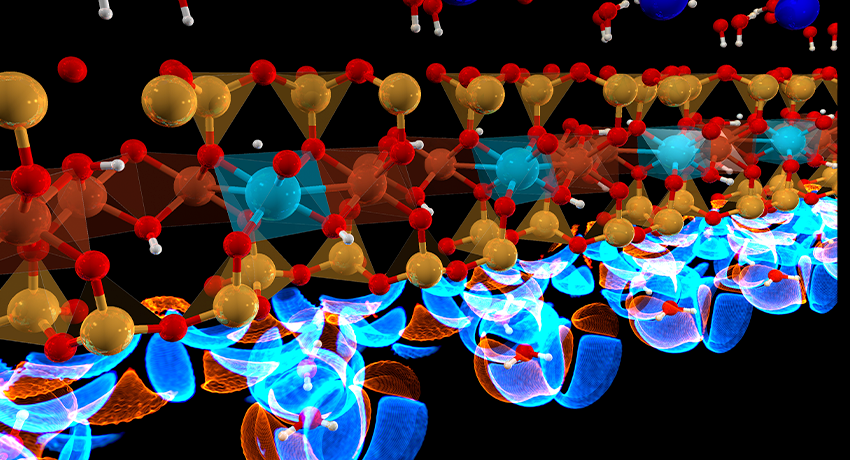

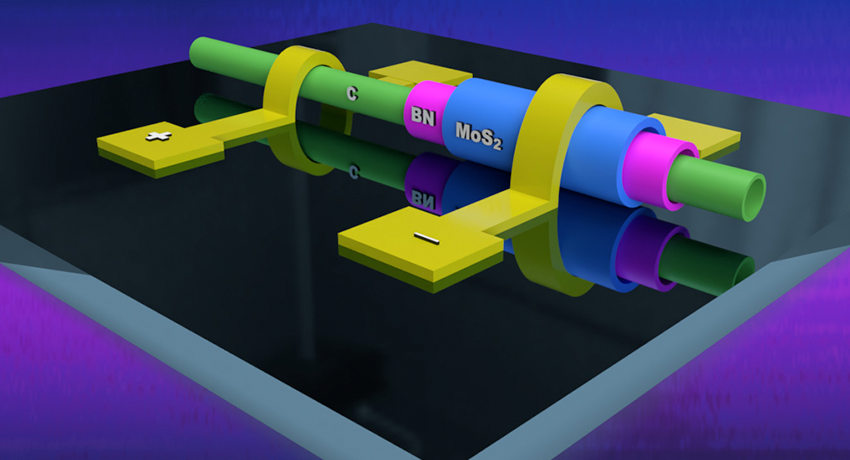

The future of materials research is nearly unlimited, with tremendous opportunities in high performance and novel materials enabled by our ability to manipulate matter at the atomic and molecular scales. This size scale, which is about the same as that of biological structures, opens up a whole new world at the interface of materials and life sciences. Our research community is expanding into this new research frontier.

Penn State's MRI is proud to be one of the world leaders in materials research and to continue to push the boundaries of materials science in all applications.